2024. Markus Pfirsching

In the past, it was difficult to get all measurement data together. Nowadays, a network of data acquisition systems records and evaluates measurement data. However, process monitoring and process improvement are about to drown in the information flood of the extensive number of measurements. Customers use the Q-DAS Reporting System to obtain desired process information quickly.

One System Containing All Data (example of a real customer – anonymized)

The first project phase was about standardizing data formats. Measurement data recorded by various systems was transferred in the Q-DAS Data Format, so that a centralized SQL database can store them. This procedure standardizes and facilitates the handling of databases considerably. During the entire production process, all measurement data is now completely available for evaluation. The simplification of IT structures is another advantage as only the maintenance of the Q-DAS system is left.

The Reporting System accesses the centralized data pool in defined intervals and evaluates it. After the statistical evaluation, a report is provided containing desired information such as characteristics and significant graphics. These reports are saved as PDF files or are sent via e-mail to defined recipients. Recipients receive only those reports that are of interest to them. Even persons who do not use statistical software like qs-STAT benefit from those reports. The reports are attached to e-mails in PFD file format and therefore, any recipient can open them. The contents of the report depend on the recipient’s field of responsibility. Each task requires specific information. The foreman, for example, receives detailed results per characteristic and machine whereas product designers and management get appropriate, comprehensive reports. There are various ways to configure the Reporting System according to the desired evaluation interval and information.

During the installation phase, Q-DAS and the customer’s employees created reports together in teamwork with the recipients of the respective reports. The OEM had defined the contents of the reports in advance depending on the recipient’s requirements. For this reason, any recipient will optimally benefit from these reports. By now, changes in the Reporting System are configured and managed automatically.

Information about Manufacturing Quality

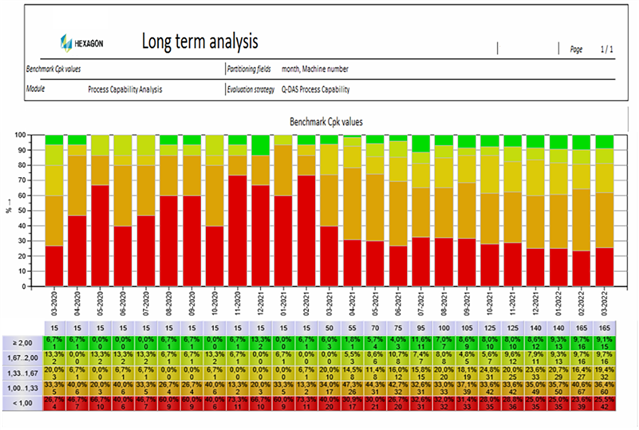

Contents are appropriate to the corresponding recipient. There is no need to search huge reports or columns of figures for information that are supposed to be important. The focus is on relevant results and graphics. In Q-DAS reports, weak points can be realized immediately without comparing different reports about different factors. Q-DAS reports bring transparency into production processes, show clear connections and the possible solutions. This saves time and shows previously undetected improvement potential. Today, quality improvement and further developments can profit from this new information and time savings. There is no need to invest in the adaption of layouts and data preparation anymore. Due to this system, it is impossible to miss deviations from predetermined quality requirements. This minimizes the danger of deficits caused by insufficient or obsolete information.

The customer is positive about the success of the project. The system detects more weak points than any other solution before. A quick statement about the quality of parts is now possible. It is generated out of one single report. Reports can be extended, special reports can be created and quick statements about the quality of parts can be made at any time.

Different measuring instruments in manufacturing and in metrology labs transfer data directly to the Q-DAS Reporting System. This enables the integration of new systems later on. Clear report graphics inform the management about the long-term performance of product quality. Therefore, they can see whether improvements had a positive, lasting effect.

Today, there is a greater benefit derived from recorded measurement data than before the start of the project. Due to the new reporting system, the optimization of reporting procedures facilitates a department-wide, real-time evaluation and the improvement and maintenance of a high manufacturing quality.