Hello everyone

I would like to share with you a little issue I am facing and if someone can advise me about how solve this little problem

I have a collection of points (APTs) already radius corrected which are part of one cylinder inspection I'm doing, my request is to build a cylinder from these points, but the cylinder calculated must have a specific diameter, the center of main axis and direction are free

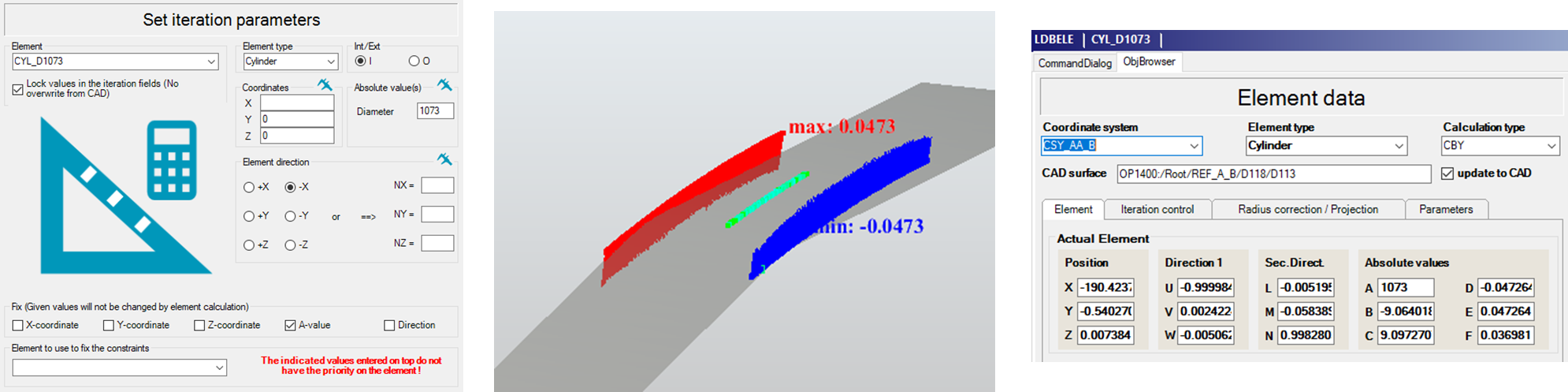

What I'm doing is to use the SETITR command to constrain the diameter:

SETITR (NAM=CYL_D1073, TYP=CYL, Y =0, Z =0, VAL=1073, DIR=-X, INO=I, FIX=N, FIY=N, FIZ=N, FID=N, FIA=Y, LCK=Y)

BuildCyl (NAM=CYL_D1073, CSY=CSY_AA_B, MOD=(NOM,NOE), INO=I, ITY=CBY, CAD=N)

bellow the mask of SETITR and the deviation of the APTS from the calculated cylinder, is possible to see the diameter was well constrained in the right image

But from my appreciation I see the cylinder was not fitted correctly, there is a missing adjusting which can minimize the deviation we see in the image above

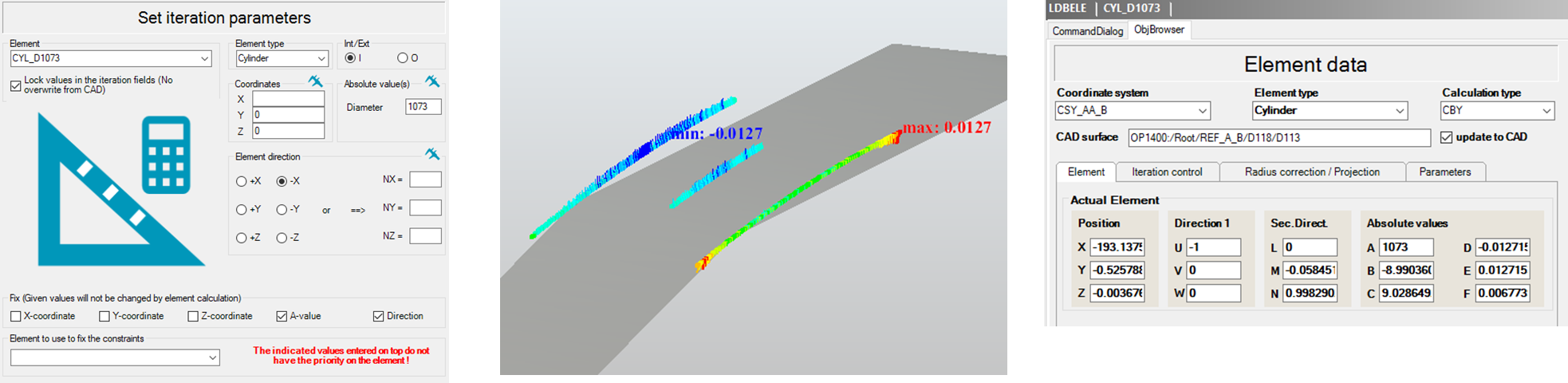

now if I fix the direction the deviations decrease, out of my compression because with more restrictions the deviation would increase:

SETITR (NAM=CYL_D1073, TYP=CYL, Y =0, Z =0, VAL=1073, DIR=-X, INO=I, FIX=N, FIY=N, FIZ=N, FID=Y, FIA=Y, LCK=Y)

BuildCyl (NAM=CYL_D1073, CSY=CSY_AA_B, MOD=(NOM,NOE), INO=I, ITY=CBY, CAD=N)

I want to work with the setting in the first example (only with the diameter constrained) but is not really minimizing the deviation as I believe it should work, do you have any suggestion to improve this?

Thanks a lot, in advance.