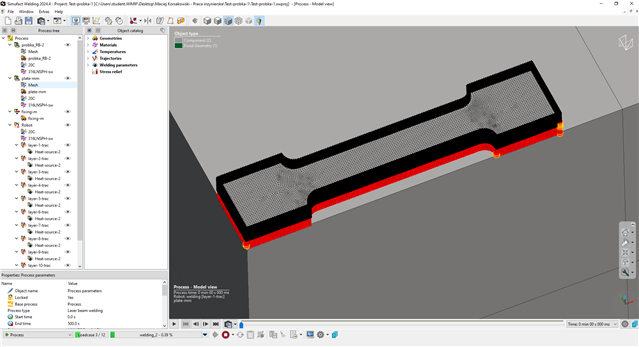

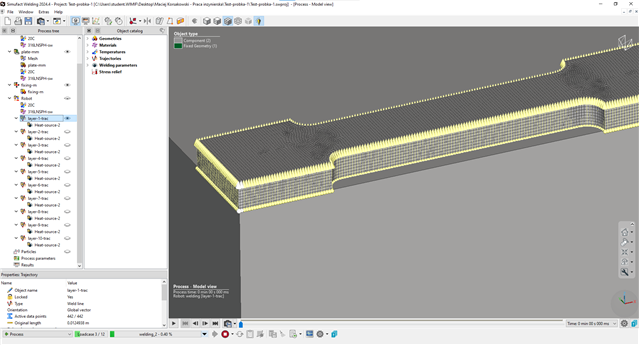

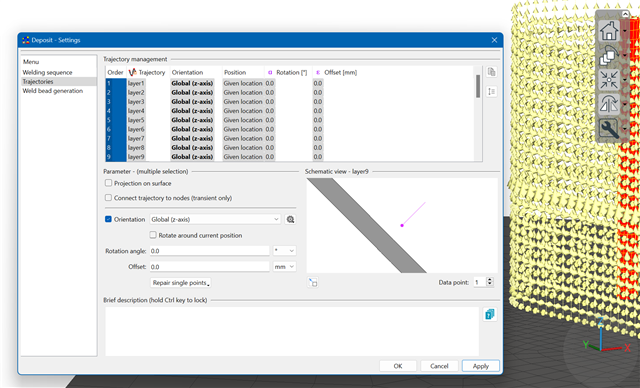

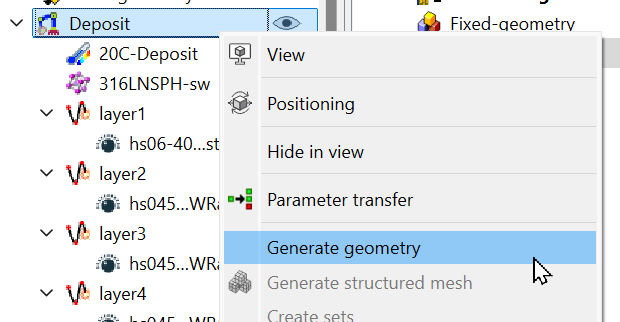

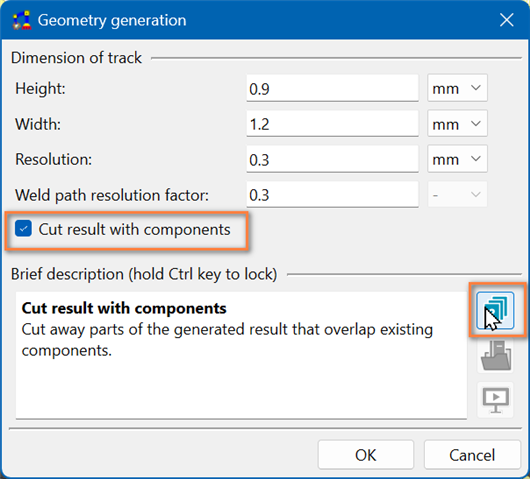

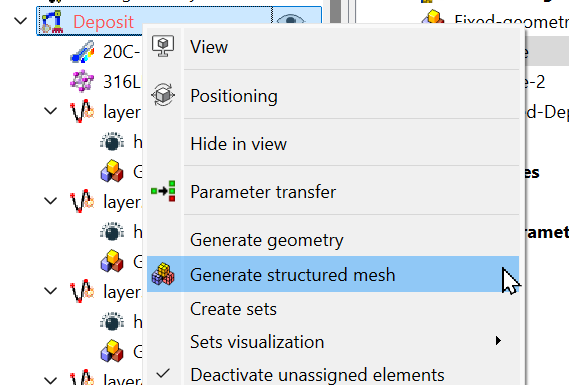

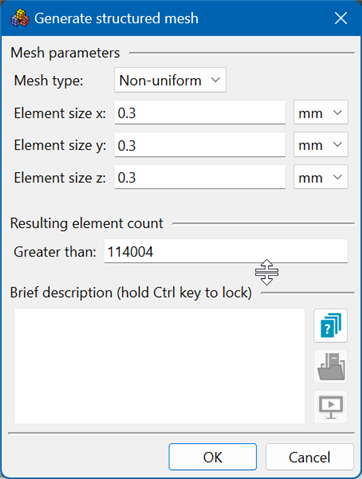

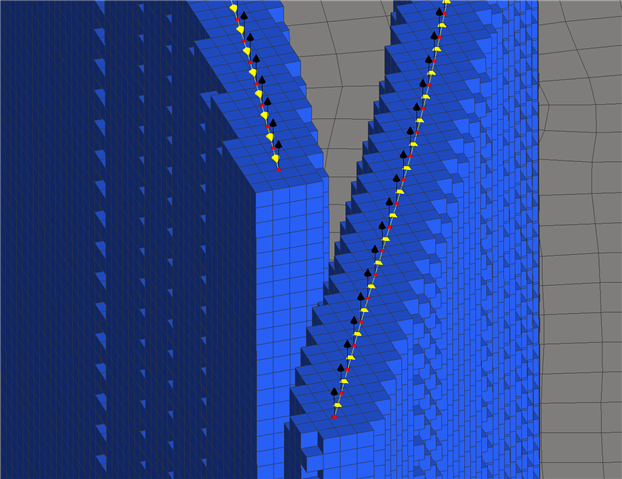

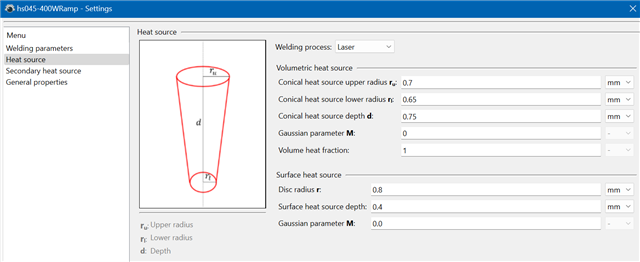

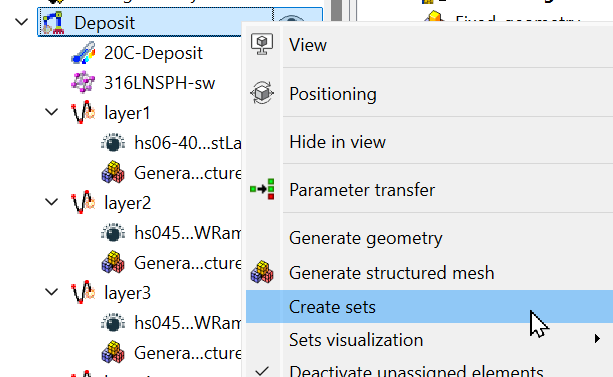

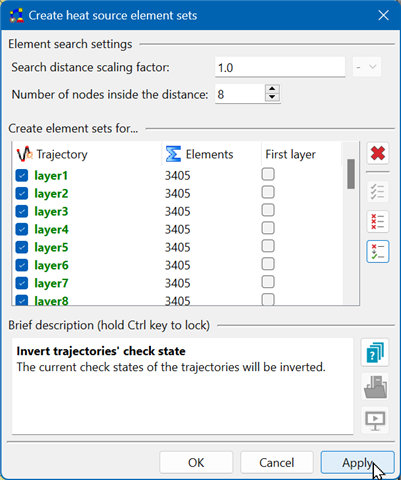

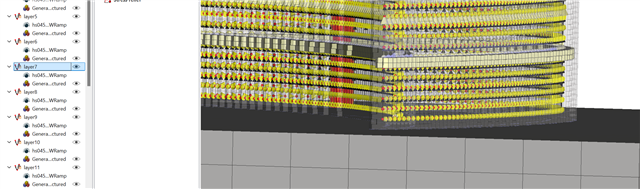

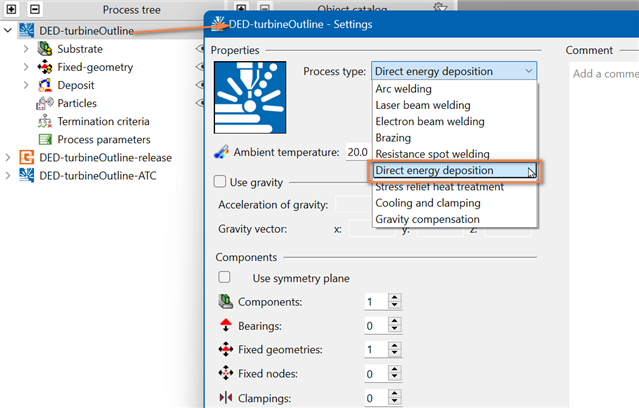

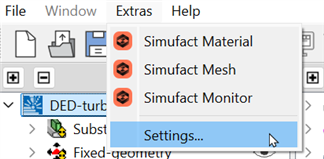

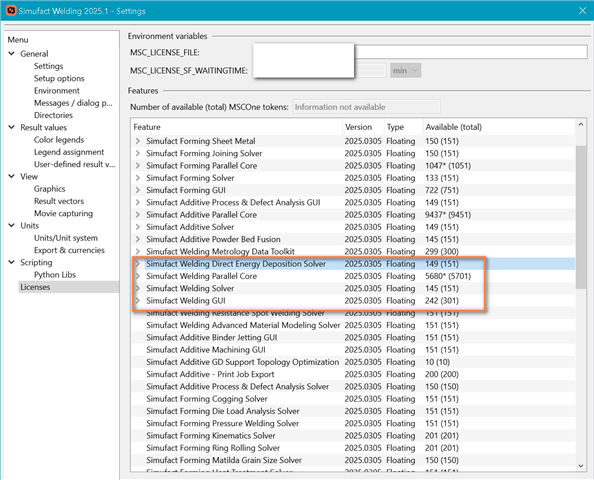

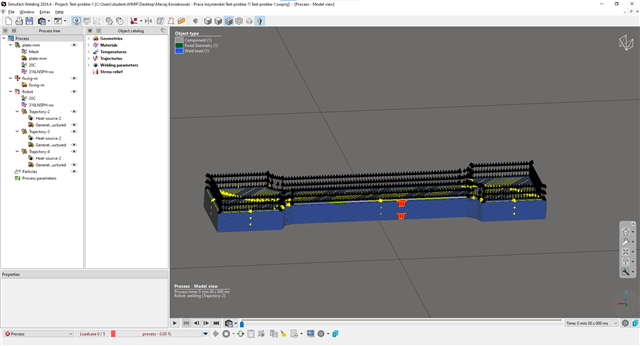

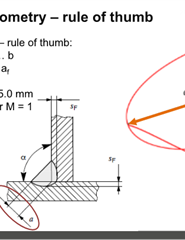

Hi, i have a problem with my multilayer simulation. I dont really know whats wrong because i am doing it for the first time with tutorial from hexagon to simulate my 3d model. For now i have problem with how to get fillers for each trajcetory (in tutorial they were made and we are just using them). Additionally i think my trajectories are done incorrectly and also like in fillers, we are just importing them so i don't know how to make them the right way. I am attaching some screenshots. If anyone could help me I would be very grateful.