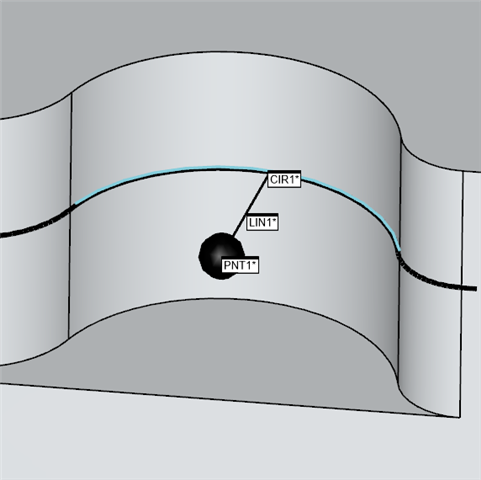

I'm trying to measure a bunch of radii from scanned data. They have all varying arc lengths. Some much less that the suggested 90°. So, I was going to create offset points from the nominal center of all the constructed arcs. Then use the nominal center points and a point from the arc (ex: CIR1.HIT[CIR1.NUMHITS/2]) and create a best fit line then measure the length of the line to get the size of the radius. I've got approximate 350 constructed circles from scan segment. So I'm trying to write a code to construct the points and the lines. For the record, I have no idea what I'm doing. I've just cobbled together a few things I've seen on here. I get the code to run without error but nothing happens. No features get created. What am I doing wrong?

Sub Main()

Dim PCDApp As Object

Dim PCDPartPrograms As Object

Dim PCDPartProgram As Object

Dim PCDCommands As Object

Dim PCDCommand As Object

Dim cmd As Object

Set PCDApp = CreateObject("PCDLRN.Application")

Set PCDPartPrograms = PCDApp.PartPrograms

Set PCDPartProgram = PCDApp.ActivePartProgram

Set PCDCommands = PCDPartProgram.Commands

Dim NumFeat As Integer

Dim NumSelect As Integer

Dim I As Integer

Dim MidHit As Integer

Dim nX as Double

Dim nY as Double

Dim nZ as Double

Dim CircName As String

Dim CenterPtName As String

Dim RadLineName As String

Dim CircCenter

Dim PCDFeatCmd

NumFeat = 0

NumSelect = 0

' Enumerate commands

For Each PCDCommand In PCDCommands

' Constructed feature

If PCDCommand.IsConstructedFeature And PCDCommand.Feature = CONST_SCAN_SEG_ARC Then

CircName(NumFeat) = PCDCommand.ID

CenterPtName = CircName & "_CENTER"

RadLineName = CircName & "_RADLINE"

Set PCDFeatCmd = PCDCommand.FeatureCommand

Set CircCenter = PCDFeatCmd.GetPoint(FPOINT_CENTROID, FDATA_THEO, CircName)

nX = CDbl(CircCenter.X)

nY = CDbl(CircCenter.Y)

nZ = CDbl(CircCenter.Z)

MidHit = PCDCommand.GetText(N_HITS, 0) / 2

'CREATE OFFSET CENTERPOINT

Set cmd = PCDCommands.Add(511, True)

retval = cmd.PutText (nX, F_OFFSET, 1)

retval = cmd.PutText (nY, F_OFFSET, 2)

retval = cmd.PutText (nZ, F_OFFSET, 3)

retval = PCDCommand.PutText (CenterPtName, ID, 0)

retval = PCDCommand.SetToggleString ("ORIGIN", REF_ID, 0)

retval = PCDCommand.SetToggleString (1, COORD_TYPE, 0)

'CREATE BF RADIUS LINE

Set cmd = PCDCommands.Add(541, True)

retval = PCDCommand.PutText (CenterPtName, REF_ID, 1)

retval = PCDCommand.PutText (CircName & ".HIT[" & MidHit & ".." & MidHit & "]", REF_ID, 2)

retval = PCDCommand.PutText (RadLineName, ID, 0)

If (NumFeat < 1000) Then

NumFeat = NumFeat + 1

End If

End If

Next PCDCommand

PCDPartProgram.RefreshPart

'***** Cleanup

Set PCDCommand = Nothing

Set PCDCommands = Nothing

Set PCDPartProgram = Nothing

Set PCDPartPrograms = Nothing

Set PCDApp = Nothing

'*****

End Sub

typo

[edited by: Cliff Stearns at 5:01 PM (GMT -5) on May 9, 2025]