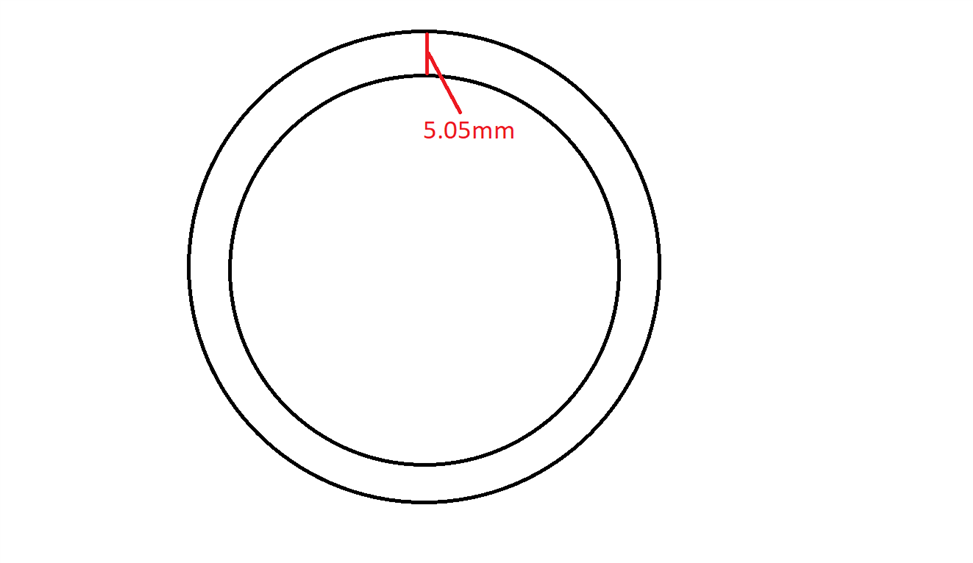

I am having a bit of an issue trying to measure 2 concentric circles and get the distance between the two. No matter what work plane or measurement strategy, I cannot get the measurement I am looking for. I have attached a simple drawing of what exactly I am trying to do. Even in an offline environment straight from the CAD, I am not getting the 5.05 I am looking for. What I am currently doing to get this measurement is taking a a point at X-0 on both circles and calling the distance that way. The issue with that is we have a very small tolerance (-0, +0.05mm) and I am not getting repeatable results using this method. If anyone here as some insight on what I might be doing incorrectly that would be fantastic!

Thanks!