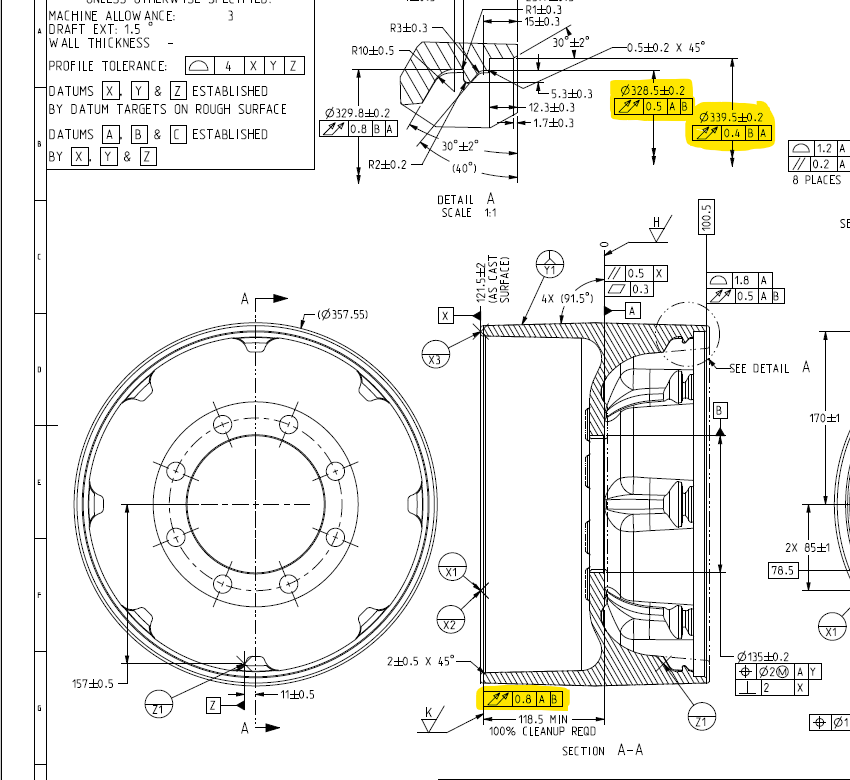

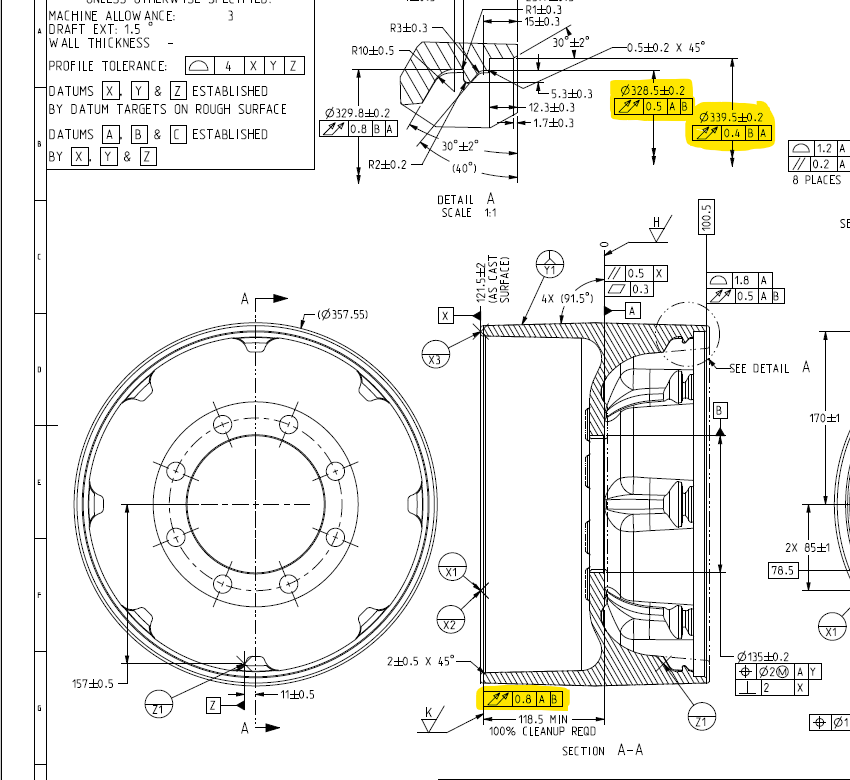

I haven't had to dimension total runout yet programming. I am fairly new with programming and was looking for some advice on the best way to dimension these Total Runout callouts.

Your Products have been synced, click here to refresh

| © 2024 Hexagon AB and/or its subsidiaries. | Privacy Policy | Cloud Services Agreement |