Let me start off by saying I just took the hexagon 201 course so I am trying to get more familiar with it here at work.

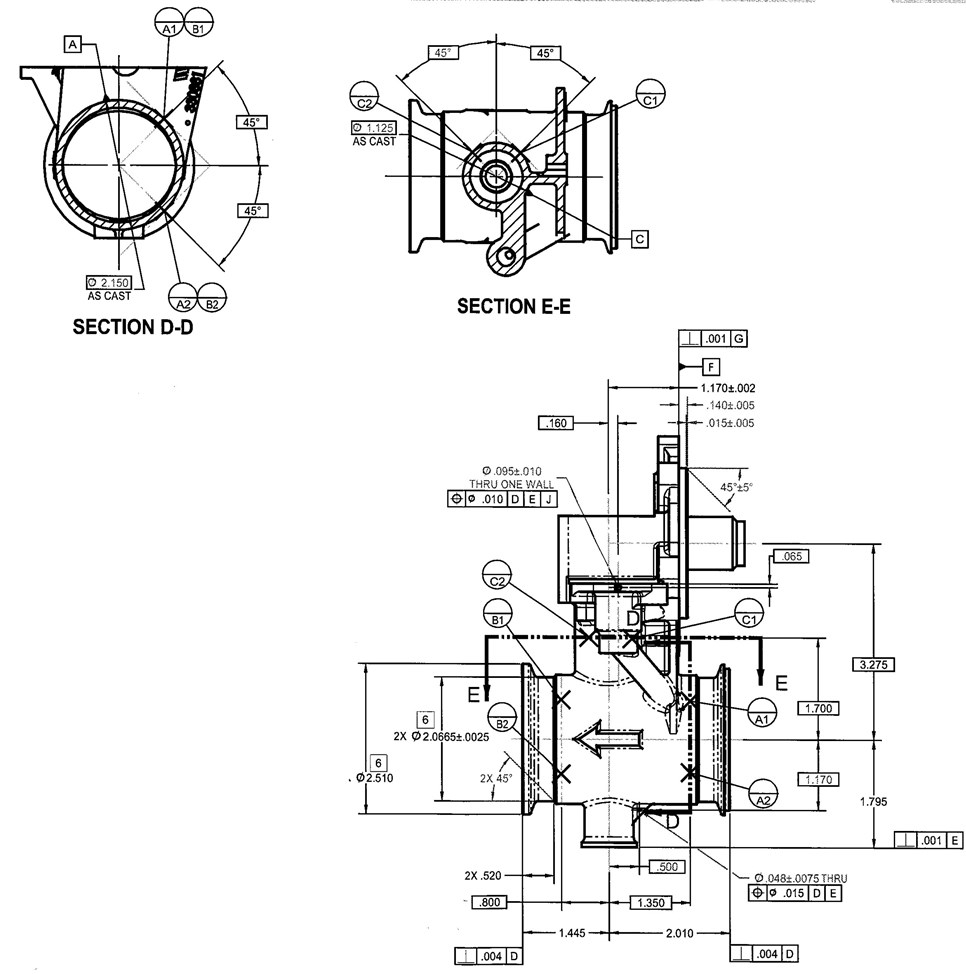

At my company we work with a lot of castings. They usually use datum targets to identify datum A, B, and C. I Have attached a part I am currently working on with the relevant information. As you can see it has two points for A, two for B and two for C. How would you use these points for an iterative alignment? As far as I have read through the forums I've only seen examples with the 3-2-1 method. When I try using 2 points to level it just give me a message saying I need 3 points. I have seen on the pcdmis website a table saying I could use 3 circles in DCC mode but not much more information on that.

Thank you for your help.