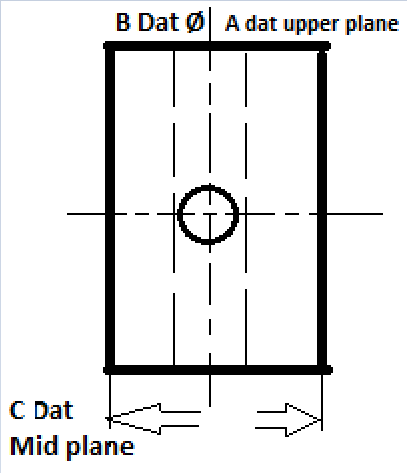

Sorry for the dump question (and draft paint image) but I am a bit confused:

I have a TP callout for the hole (center of image) on a part like that. Datum A is the Upper plane (basic dimension value not important), Datum B is the vertical Ø through the part as displayed in dashed lines and Datums C as per picture. The callout is A/B/C and I was wondering since C is controlling the rotation in this datum structure, it would be wrong to control this hole as a circle right ? It would need to be a cylinder...

Thanks in advance for your help