Your Products have been synced, click here to refresh

Your Products have been synced, click here to refresh

PLN_A =FEAT/CONTACT/PLANE/DEFAULT,CARTESIAN,NONE,LEAST_SQR

THEO/<72.292,28.107,0>,<0,0,1>

ACTL/<72.292,28.107,0>,<0,0,1>

TARG/<72.292,28.107,0>,<0,0,1>

ANGLE VEC=<1,0,0>,SQUARE

SHOW FEATURE PARAMETERS=NO

SHOW CONTACT PARAMETERS=NO

PLN_B =FEAT/CONTACT/PLANE/DEFAULT,CARTESIAN,NONE,LEAST_SQR

THEO/<0,51.21,-10.611>,<-1,0,0>

ACTL/<0,51.21,-10.611>,<-1,0,0>

TARG/<0,51.21,-10.611>,<-1,0,0>

ANGLE VEC=<0,0,1>,SQUARE

SHOW FEATURE PARAMETERS=NO

SHOW CONTACT PARAMETERS=NO

PLN_C =FEAT/CONTACT/PLANE/DEFAULT,CARTESIAN,NONE,LEAST_SQR

THEO/<49.195,60,-5.825>,<0,1,0>

ACTL/<49.195,60,-5.825>,<0,1,0>

TARG/<49.195,60,-5.825>,<0,1,0>

ANGLE VEC=<-1,0,0>,SQUARE

SHOW FEATURE PARAMETERS=NO

SHOW CONTACT PARAMETERS=NO

A1 =ALIGNMENT/START,RECALL:STARTUP,LIST=YES

ALIGNMENT/LEVEL,ZPLUS,PLN_A

ALIGNMENT/ROTATE,YPLUS,TO,PLN_C,ABOUT,ZPLUS

ALIGNMENT/TRANS,XAXIS,PLN_B

ALIGNMENT/TRANS,YAXIS,PLN_C

ALIGNMENT/TRANS,ZAXIS,PLN_A

ALIGNMENT/END

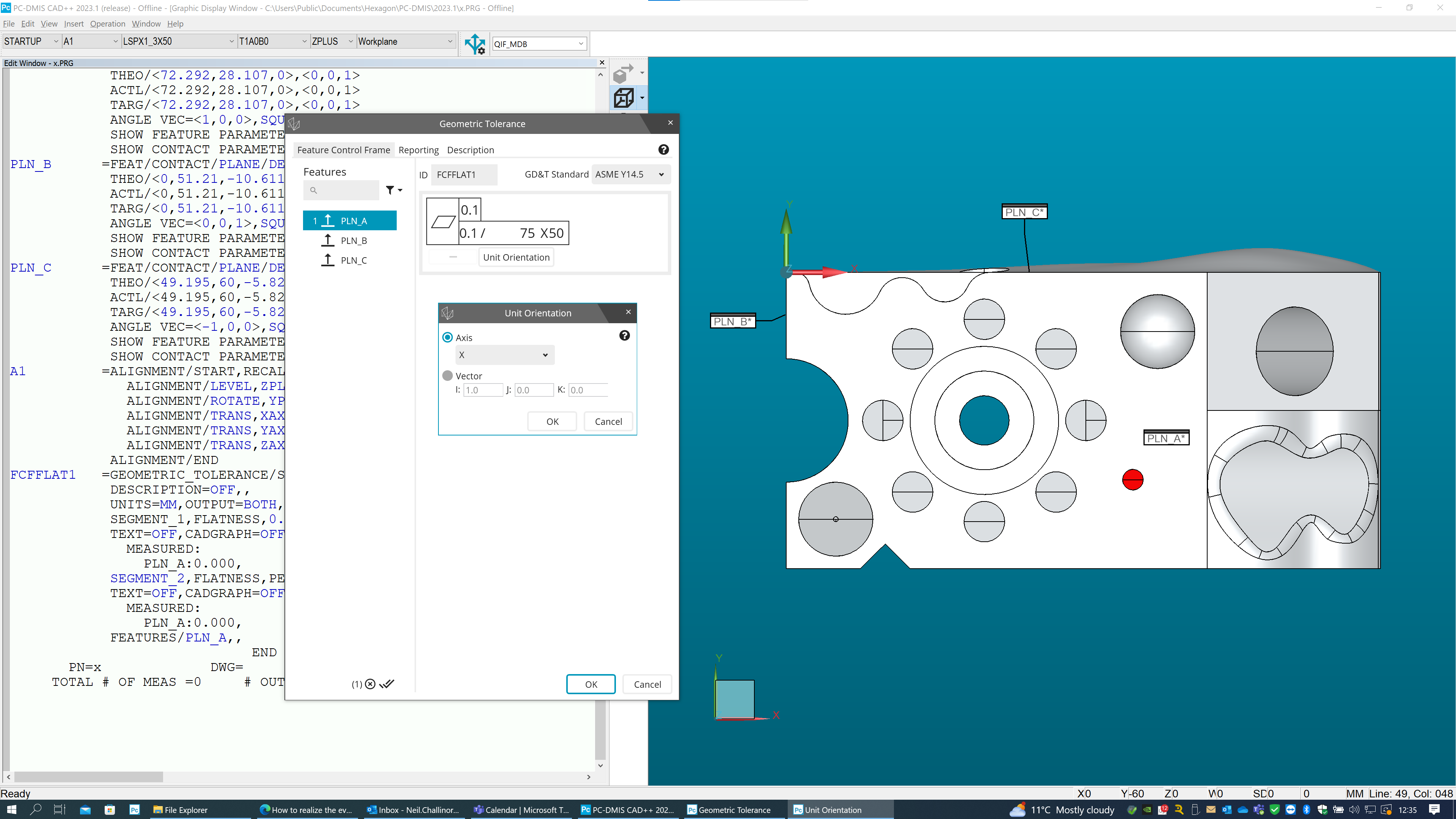

FCFFLAT1 =GEOMETRIC_TOLERANCE/STANDARD=ASME Y14.5,SHOWEXPANDED=YES,

DESCRIPTION=OFF,,

UNITS=MM,OUTPUT=BOTH,ARROWDENSITY=100,

SEGMENT_1,FLATNESS,0.1,TOL_ZONE_MATH=DEFAULT,

TEXT=OFF,CADGRAPH=OFF,REPORTGRAPH=OFF,MULT=10,

MEASURED:

PLN_A:0.000,

SEGMENT_2,FLATNESS,PER_UNIT,0.1,<UA>,75,50,<1,0,0>, <- (this sets the orientation of the 75mm long edge so that it is running along the X-axis)

TEXT=OFF,CADGRAPH=OFF,REPORTGRAPH=OFF,MULT=10,

MEASURED:

PLN_A:0.000,

FEATURES/PLN_A,,

PLN_A =FEAT/CONTACT/PLANE/DEFAULT,CARTESIAN,NONE,LEAST_SQR

THEO/<72.292,28.107,0>,<0,0,1>

ACTL/<72.292,28.107,0>,<0,0,1>

TARG/<72.292,28.107,0>,<0,0,1>

ANGLE VEC=<1,0,0>,SQUARE

SHOW FEATURE PARAMETERS=NO

SHOW CONTACT PARAMETERS=NO

PLN_B =FEAT/CONTACT/PLANE/DEFAULT,CARTESIAN,NONE,LEAST_SQR

THEO/<0,51.21,-10.611>,<-1,0,0>

ACTL/<0,51.21,-10.611>,<-1,0,0>

TARG/<0,51.21,-10.611>,<-1,0,0>

ANGLE VEC=<0,0,1>,SQUARE

SHOW FEATURE PARAMETERS=NO

SHOW CONTACT PARAMETERS=NO

PLN_C =FEAT/CONTACT/PLANE/DEFAULT,CARTESIAN,NONE,LEAST_SQR

THEO/<49.195,60,-5.825>,<0,1,0>

ACTL/<49.195,60,-5.825>,<0,1,0>

TARG/<49.195,60,-5.825>,<0,1,0>

ANGLE VEC=<-1,0,0>,SQUARE

SHOW FEATURE PARAMETERS=NO

SHOW CONTACT PARAMETERS=NO

A1 =ALIGNMENT/START,RECALL:STARTUP,LIST=YES

ALIGNMENT/LEVEL,ZPLUS,PLN_A

ALIGNMENT/ROTATE,YPLUS,TO,PLN_C,ABOUT,ZPLUS

ALIGNMENT/TRANS,XAXIS,PLN_B

ALIGNMENT/TRANS,YAXIS,PLN_C

ALIGNMENT/TRANS,ZAXIS,PLN_A

ALIGNMENT/END

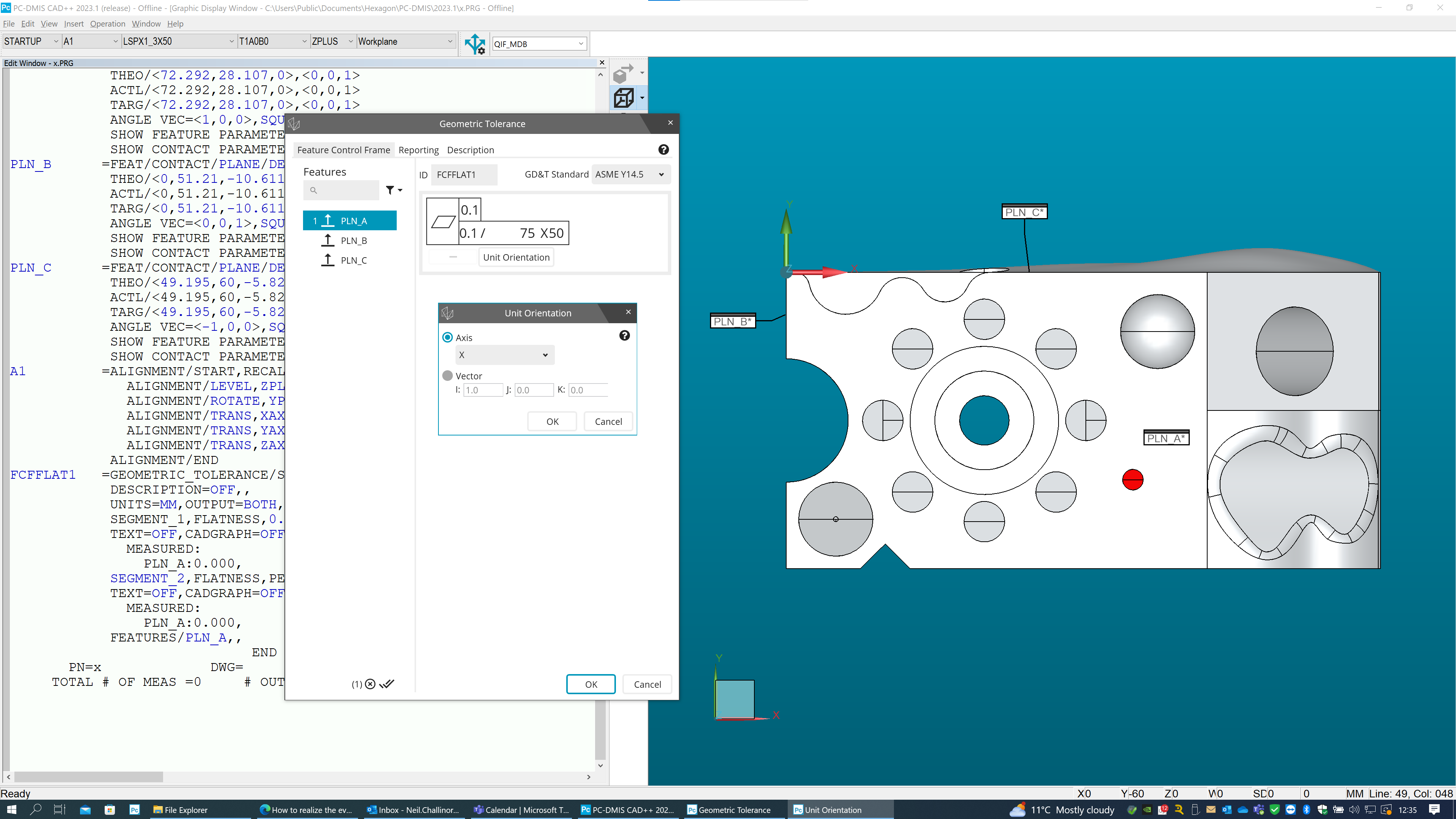

FCFFLAT1 =GEOMETRIC_TOLERANCE/STANDARD=ASME Y14.5,SHOWEXPANDED=YES,

DESCRIPTION=OFF,,

UNITS=MM,OUTPUT=BOTH,ARROWDENSITY=100,

SEGMENT_1,FLATNESS,0.1,TOL_ZONE_MATH=DEFAULT,

TEXT=OFF,CADGRAPH=OFF,REPORTGRAPH=OFF,MULT=10,

MEASURED:

PLN_A:0.000,

SEGMENT_2,FLATNESS,PER_UNIT,0.1,<UA>,75,50,<1,0,0>, <- (this sets the orientation of the 75mm long edge so that it is running along the X-axis)

TEXT=OFF,CADGRAPH=OFF,REPORTGRAPH=OFF,MULT=10,

MEASURED:

PLN_A:0.000,

FEATURES/PLN_A,,

| © 2025 Hexagon AB and/or its subsidiaries. | Privacy Policy | Cloud Services Agreement |