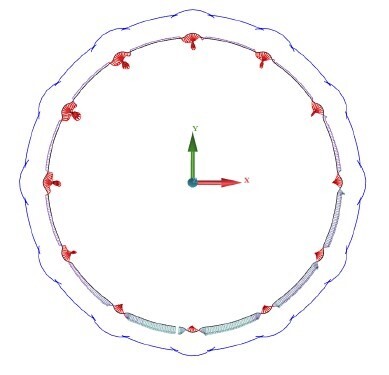

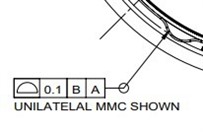

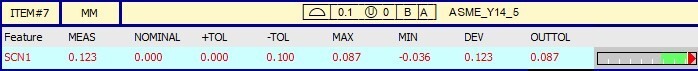

So long story short, I've never used the analysis views. My question is the does the boundary automatically project to the tolerance limit based on the cad/dimensions or is there a setting that needs input to define the profile tolerance. Management has questioned the zone that's being projected on the report and I'm uncertain of the answer. The main concern is the vectors are going both directions. This coupled with production having exhausted all the test parts they have and need to know how much to offset the profile pattern. I'm running 2019 R1 on a global green with a Leitz Scanning head.

I believe they have an issue with the machining process of the pattern. Any input is appreciated. I'm not impressed with the FCF note either, but I can interpreted the intent at least.