Your Products have been synced, click here to refresh

Your Products have been synced, click here to refresh

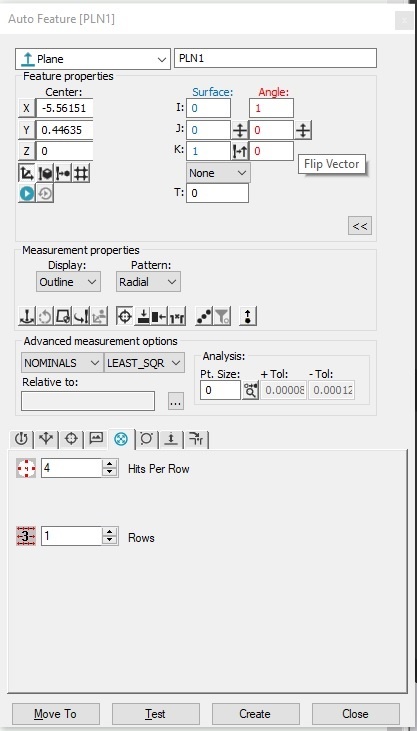

M1 =FEAT/PLANE,RECT,TRIANGLE THEO/24.893,21.517,0,0,0,1 ACTL/813.942,-100.274,-781.278,0.0000055,-0.000022,1 MEAS/PLANE,4 HIT/BASIC,NORMAL,-21.129,-14.415,-0.001,0,0,1,759.763,-122.04,-781.279,USE THEO = YES HIT/BASIC,NORMAL,-33.853,29.679,0.001,0,0,1,759.761,-76.147,-781.276,USE THEO = YES HIT/BASIC,NORMAL,70.26,59.713,-0.001,0,0,1,868.12,-76.15,-781.278,USE THEO = YES HIT/BASIC,NORMAL,84.292,11.09,0.001,0,0,1,868.123,-126.758,-781.278,USE THEO = YES ENDMEAS/ ALIGN00 =ALIGNMENT/START,RECALL:STARTUP, LIST= YES ALIGNMENT/LEVEL,ZPLUS,M1 ALIGNMENT/TRANS,ZAXIS,M1 ALIGNMENT/END .... MOVE/CLEARPLANE TIP/T1A0B0, SHANKIJK=0, 0, 1, ANGLE=16.093 MOVE/CLEARPLANE A1 =AUTO/VECTOR POINT,SHOWALLPARAMS = YES THEO/M1.HIT[1].X,M1.HIT[1].Y,0,0,0,1 ACTL/-21.129,-14.415,0,0,0,1 TARG/M1.HIT[1].X,M1.HIT[1].Y,0,0,0,1 THEO_THICKNESS = 0,RECT,SNAP = YES,$ AUTO MOVE = NO,DISTANCE = 10 MOVE/CLEARPLANE A2 =AUTO/VECTOR POINT,SHOWALLPARAMS = YES THEO/M1.HIT[2].X,M1.HIT[2].Y,0,0,0,1 ACTL/-33.853,29.679,0,0,0,1 TARG/M1.HIT[2].X,M1.HIT[2].Y,0,0,0,1 THEO_THICKNESS = 0,RECT,SNAP = YES,$ AUTO MOVE = NO,DISTANCE = 10 MOVE/CLEARPLANE A3 =AUTO/VECTOR POINT,SHOWALLPARAMS = YES THEO/M1.HIT[3].X,M1.HIT[3].Y,0,0,0,1 ACTL/70.26,59.713,-0.001,0,0,1 TARG/M1.HIT[3].X,M1.HIT[3].Y,0,0,0,1 THEO_THICKNESS = 0,RECT,SNAP = YES,$ AUTO MOVE = NO,DISTANCE = 10 MOVE/CLEARPLANE A4 =AUTO/VECTOR POINT,SHOWALLPARAMS = YES THEO/M1.HIT[4].X,M1.HIT[4].Y,0,0,0,1 ACTL/84.292,11.09,0.003,0,0,1 TARG/M1.HIT[4].X,M1.HIT[4].Y,0,0,0,1 THEO_THICKNESS = 0,RECT,SNAP = YES,$ AUTO MOVE = NO,DISTANCE = 10 MOVE/CLEARPLANE

| © 2024 Hexagon AB and/or its subsidiaries. | Privacy Policy | Cloud Services Agreement |