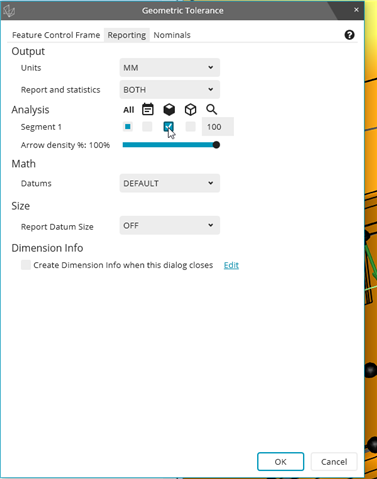

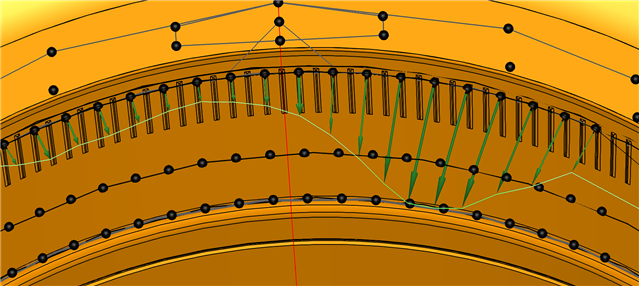

I recently changed employers, and went from a 3rd party inspection company using PCDmis 2014 to a manufacturing company using the latest and greatest (2023.1 currently). At my previous employer we also only used legacy dimensions, unless datum shift was involved, and even then we only used it if the dimensions were out of spec without datum shift. I have a unilateral profile, and I'm trying to use the report to tell the machinists where they need to make their adjustments, but I'm getting some confusing max/min results when reporting using Geotol. See the photo below (I hope this is the best way to attach a photo here)

With my deviation here only being allowed to be negative from the nominal, I'm a bit confused as to why Geotol lists a positive number for my max. Today this profile is good, but yesterday it was bad, and I was struggling with my explanation as where they needed to move. I finally just got the t values of the points that were out and used that deviation to tell them what to adjust. Can someone help me understand this?