At first the report would have the measurements from the last part in addition to the current part, but its progressed to now it shows the dimensions an increasing number of time everytime I run a part. Right now my report is 23 pages long, for about 10 dimensions. It was initially 2 pages. I can turn off the cmm and computer and the next report will be 25 pages. Last report was 19 pages. Its just making the report ridiculous and I have to give the report to a customer I don't know what to troubleshoot.

Thank you guys. I'll try to take a video in a minute here

icon which is "execute from cursor". This is classed as a partial execution and, as I said in my last comment, will append the report each time. You need to use the normal execute mode - this icon

icon which is "execute from cursor". This is classed as a partial execution and, as I said in my last comment, will append the report each time. You need to use the normal execute mode - this icon  (keyboard shortcut = CTRL+Q)

(keyboard shortcut = CTRL+Q) .

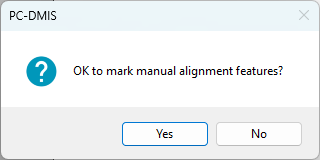

. and you will be asked if it's ok to mark manual features...

and you will be asked if it's ok to mark manual features...