how do I make the edit window display the features I'm dimensioning and be able to edit the noms and tols from the edit window and the comments I put as well all show up on the report

Your Products have been synced, click here to refresh

Your Products have been synced, click here to refresh

how do I make the edit window display the features I'm dimensioning and be able to edit the noms and tols from the edit window and the comments I put as well all show up on the report

You can use the Command mode option, where you will be able to edit in the edit window. Go to View -->Command Mode.

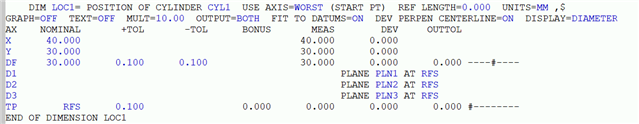

B.Vorhis_89 Can you give us a little bit more information on what it is you're trying to do? As others have said, you can display the edit window in command mode (View > Command Mode) to see the PC-DMIS command syntax. You can also edit (F9) the command to open up the respective dialog. As far as dimensions go, there are a number of different ways of dimensioning features, depending on the version of PC-DMIS you are using and the settings you are using. For example, if you have "Use Legacy Dimensions" active (Insert>Dimensions>Use Legacy Dimensions), the dimension commands will look something like this in the edit window (in command mode)...

This style of dimensioning allows you to key in nominal and tolerance information directly from the edit window.

However, if "Use Legacy Dimensions" is turned off, then you will be using feature control frame style GD&T dimensioning. In versions 4.0 - 2020 R1 this was called XactMeasure and in versions 2020 R2 onwards, it is called the Geometric Tolerance Command. Both of these methods pull the nominal information directly from the features. XactMeasure allowed limited editing of nominal information for certain types of dimension. The Geometric Tolerance command only allows you to enter upper or lower tolerance values with all nominal information coming directly from the features.

See: Can't change nominals on 2023 Geotol - PC-DMIS for CMMs - PC-DMIS - Nexus Community (hexagon.com)

I CURRENTLY USE 2023.1 IM GOING TO TRY THIS AND SEE HOW IT WORKS. YOU SEE THE PROBLEM IS I'VE BEEN SHOWN OR TOLD A DIFFERERNT WAY TO DO THINGS EVERY TIME I GET SOME HELP AND ITS REALLY HARD TO REMEMBER WHAT ROUTES TO TAKE AND FIGURE OUT WHAT ONE WORKS BEST FOR ME. I FEEL MUCH MORE CONFIDENT WITH THE RECENT ACCESS TO THIS FORUM. THANKS AGAIN FOR ALL THE INFORMATION AND ILL BE BACK IF I HIT ANYMORE SNAGS.

You could download and reference the user manual, or press f1.

user manual is here support.hexagonmi.com/.../Where-can-I-download-PC-DMIS-user-manuals

There's always multiple ways to 'skin the cat' in this software, as some users prefer one method over the other.

-Command mode editing

-Summary mode editing

-Mouseclicks + keystrokes on CAD

-Dropdown menus

-Quick access buttons (that you can even customize)

-Keystroke shortcuts (like the F buttons, CTL+Q, CTL+ALT+A for align menu, ALT+P to preview routine's path lines)

B.Vorhis_89 I deleted the your last comment showing the drawing. As others pointed out, you shouldn't post proprietary information unless you have express permission to do so. Ideally, try to post snippets of the drawing, redact any sensitive information or create a sketch of your own approximating the relevant information.

OK THANK YOU SIR FOR LETTING ME KNOW THAT. ITS FUNNY YOU SAID THAT BECAUSE WAS JUST WONDERING AFTER I LEFT WORK YESTERDAYIF I SHOULD HAVE CROPPED THE IMAGES WHICH ILL ATTEMPT TO DO NOW.

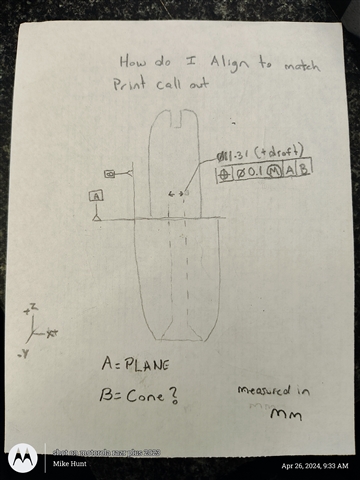

IF YOU NEED MOE INFO LET ME KNOW IVE GOT BASIC ITERATE AND DCC ITERATE ALIGN IVE MEASURED ALL FEATURES WITH PROPER ANGLE CHANGES NOWIM STUMPED ON THIS ALIGNMENT FOR THE FCF IS [A] YOUR LEVEL AND ROTATE, & [B] YOUR ORIGIN AND CAN YOU BRIEFLY EXPLAIN IF IM WRONG OR RIGHT HOW YOU FIGURE THIS OUT. IM SORRY IM VERY NEW TO THIS WORLD AND DIDNT KNW WHAT ALL THIS CAREER INTAILED WHEN I WAS OFFERERD THE POSITION. AT THE TIME I WAS TRYING TO GET JOB SECURITY, I KNOW I CAN GET IT WITH A LITTLE GUIDANCE IM SO GREATFUL FOR ALL THE SUPPORT

Align command:

Level Z+ to your A datum plane.

--You have no effective rotation datum (about A) defined on the print. I would use the bottom plane of the mount point for that device as my rotation datum. (or a simulated inverse IE use 1-2-3 blocks to set part on machine, with 123's sticking out and measure a plane on top of the protruding 123 block surfaces)

So Rotate to Y+ about Z axis, to that base plane.

--I would consider B datum as a circle upon intersecting the A datum plane (or relatively close). Measure B datum as a circle close to A.

Origin X&Y to B datum

Origin Z to A datum.

done :D

then, measure your inner cylinder/cone, which is a cylindrical tolerance zone that's perpendicular to A, and centered about B.

| © 2025 Hexagon AB and/or its subsidiaries. | Privacy Policy | Cloud Services Agreement |