Hello PC-DMIS forum,

I have a question regarding Diametric clearance and how measuring a diameter with GD&T DEFUALT changes the measurement.

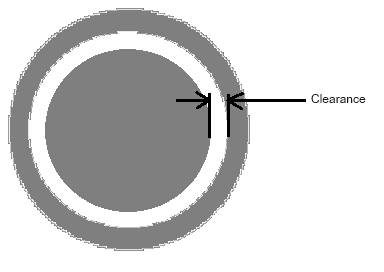

we are machining 2 pieces for a welded ring the inner ring must fit into the outer ring. the tolerance for the outer is 10.320-10.316 (inches) and the inner diameter is 10.615-10.610 with a note stating the diametric clearance between the two should be .0005 to .0025

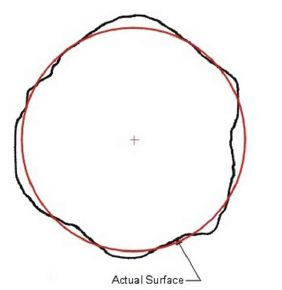

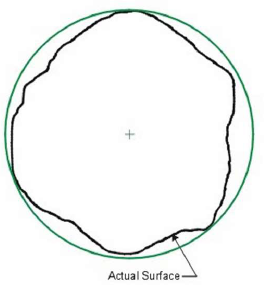

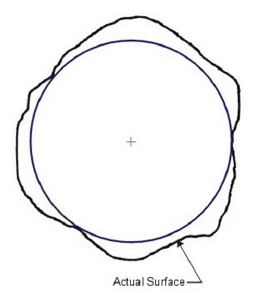

I am calculating the diameter using the normal dimensioning tool and outputting the data through DEFULT on a GD&T callout. the GD&T callout makes the inner rings O.D. bigger while making the I.D. smaller and making the diametric clearance look better.

my question is, is using the DEFUALT tolerancing for the diameter more right to achieve the callout the print is asking for?

I have never dealt with diametric clearances on any other part so any advice would be helpful. Thank you,