Hello all.

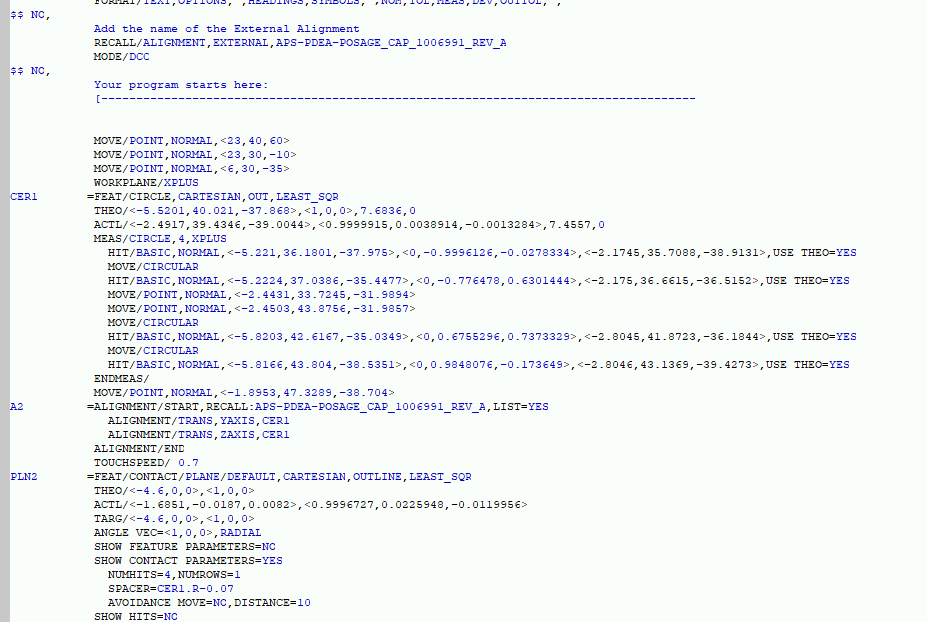

So I am having this issue where in one of my programs the DCC alignment fails but only when I execute the program from Inspect (version5.1.210.0) and not within PCdmis V2017 R2. The program starts correctly, probes a circle and then moves 10mm away in inspect trying to probe the plane. In PCdmis, the plane is probed as expected and the program continues.

The program is in a read only location for many many years and all this time using PCdmis we did not have any issue. Using inspect, the problem arises. I also tested in a second machine and same thing happens. I though Inspoect was a UI portal for the operator so what gives?

Any help will be much appreciate it.

PS: The program cannot be revised that easily and any change takes ages in my enterprise and this issue is impacting production and also makes production and management think less of me as I opted for Inspect :S

Your Products have been synced, click here to refresh