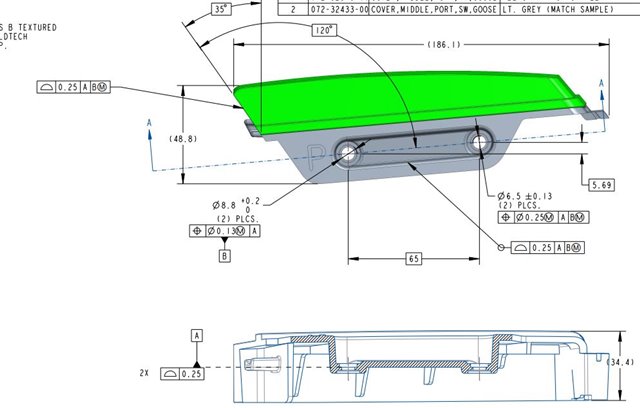

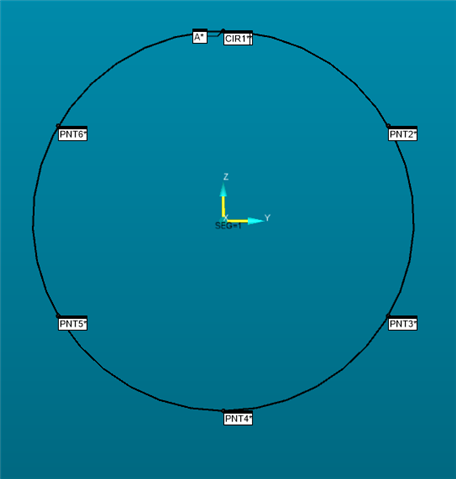

I've attached an image of a part I'm working on and I always get confused by seeing only two datums I'm not sure how to go about creating my alignment my alignment I know this is basic stuff but I'm with limited training on top of being the only operator In the company so there is no mentor/co-worker to turn to please keep answers simplistic as I previously stated I am basically self-taught and terminology isn't my strong suite as of yet. Please and Thanks to all in advance. I can add more info as needed just let me know.