Has anyone dealt with a non-uniform profile tolerance zone? If so, how is it programmed in pc-dmis?

Your Products have been synced, click here to refresh

Has anyone dealt with a non-uniform profile tolerance zone? If so, how is it programmed in pc-dmis?

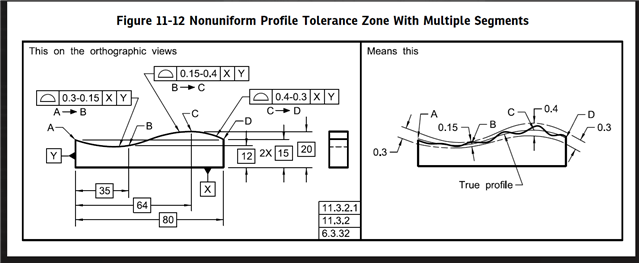

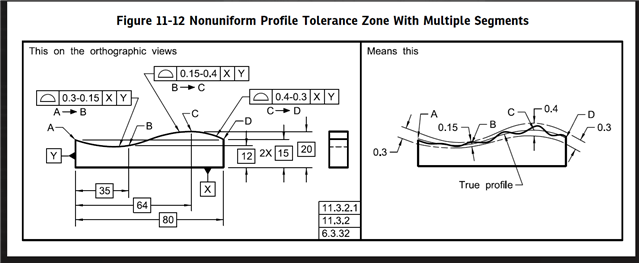

PC-DMIS does not currently support nonuniform profile tolerance zones. Measure each segment individually and apply a simultaneous evaluation (if applicable).

How does the simultaneous evaluations work. I know they exist, but I have never had the need to use it.

When your Datum Reference Frame (DRF) doesn't fully constrain all 6 Degrees of Freedom (DoF) you can have datum shift (or datum feature displacement). As an example, imagine a primary datum plane and a secondary datum cylinder perpendicular to primary. The DRF does not constrain rotation about the primary datum normal vector, so that freedom in rotation can be taken advantage of. Imagine a second cylinder perpendicular to primary. If it were positioned back to primary and secondary, the DRF will rotate in such a way that will minimize the actual value. If you have a third cylinder positioned the same way (same DRF), they must be evaluated simultaneously (i.e. the rotation that is performed to minimize an actual value cannot be different for different features as that would not represent true function).

In essence, all position and profile tolerances utilizing the same DRF need to be evaluated simultaneously. Refer to ASME Y14.5-2018 Para. 7.19.

In the past I have cheated on this, I just had the CNC programmers spit me out a model that has the surfaces adjusted to their "nominal" location per what the drawing states in the FCF. It is not perfect, but it will let you tell the machinists its good.

The final profile measured value would be treated the same as a regular profile from my understanding. But to determine the profile is out of tolerance you would need to evaluate each location along the segment. You could place points on the CAD along with the segment and create a constructed feature set. Tolerance a profile to the scan set you create to set a profile. Then report T values for the points to see deviations at specific locations.

| © 2025 Hexagon AB and/or its subsidiaries. | Privacy Policy | Cloud Services Agreement |