Hello,

I am new to CMM programing and have hit a snag. I am trying to create a plane sperate from my CAD drawling so I can raise my part off the granite. How ever I need this plan to allow me to zero it. Like you would do for a manual CMM. When I went to program the plane, I told the vectors that it was <0,0,1> instead of <0,0, -1> . I leveled and origin to the plane in both manual and DCC. Then moved working with the CAD drawling, I was hoping that when I create a plane on the inside of the part that it would recognize that the part was on top of the plane.

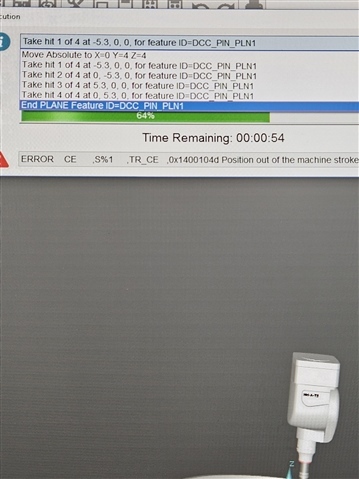

How ever after I finished doing the manual and DCC alignments for the actual CAD drawling and then went to do the first play though, the CMM errored out each time after trying to take the first four hits for the plane underneath the CAD drawling.

So, my question is, is it possible to create a raised plane off the granite and if so,, how do you do this? Any help would be greatly appreciated, thank you for your time.