I’ve been working with PC-DMIS and noticed discrepancies when analyzing surface profile callouts on grouped scanned data. Here’s what I’m observing, and I’d like to confirm if my understanding of the underlying calculations is correct.

Observations:

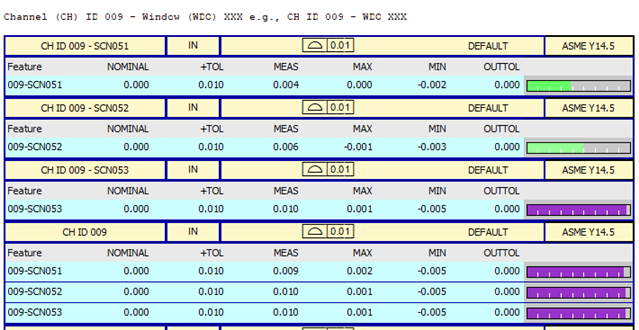

- I collected three scans at different z-heights:

- Scan 009-SCN051: Taken at -0.13175 z-height.

- Scan 009-SCN052: Taken at -0.2505 z-height.

- Scan 009-SCN053: Taken at -0.36925 z-height.

- When I create a surface profile callout on the grouped scans, the result differs from what I expected based on the individual scan data. The new result appears to be a blended or averaged deviation across the combined dataset.

Context and Assumptions:

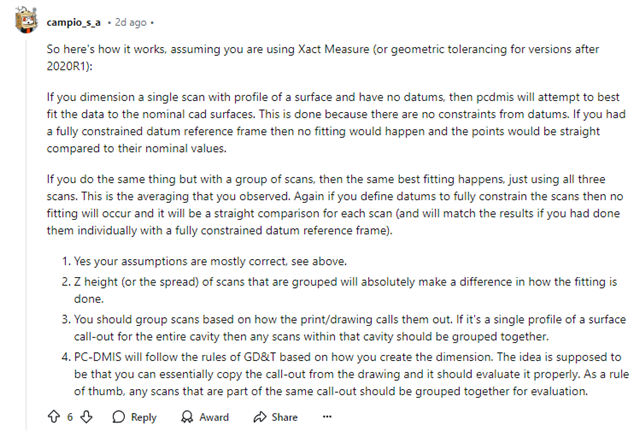

Here are my assumptions about how PC-DMIS handles surface profile calculations:

- When a surface profile callout is applied to a single scan, PC-DMIS calculates deviations relative to the nominal values for that scan alone.

- When multiple scans are grouped, PC-DMIS merges the datasets and recalculates deviations relative to the entire combined set of points. This often results in a “blended” statistical representation that differs from individual scan results.

- The variation in z-heights may influence the combined calculation, potentially leading to differences in the grouped analysis compared to the individual datasets.

My Questions:

- Are my assumptions about how PC-DMIS processes individual and grouped scans for surface profile callouts accurate? If not, what is the correct explanation?

- How does the variation in z-heights (where the scans were taken) impact the combined surface profile calculation? Would alignment inconsistencies between scans exaggerate these differences?

- For reporting purposes, should I prioritize individual scan results for localized accuracy, or the grouped scan result for a global deviation? Does this depend on specific application requirements?

- Are there best practices or settings in PC-DMIS to ensure consistency when handling grouped scans for surface profile callouts?

I’d appreciate any insights or guidance on whether my understanding is correct and how best to approach this scenario in PC-DMIS. Thank you!

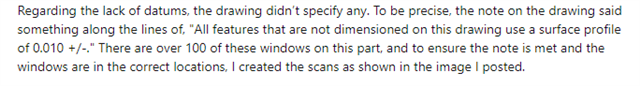

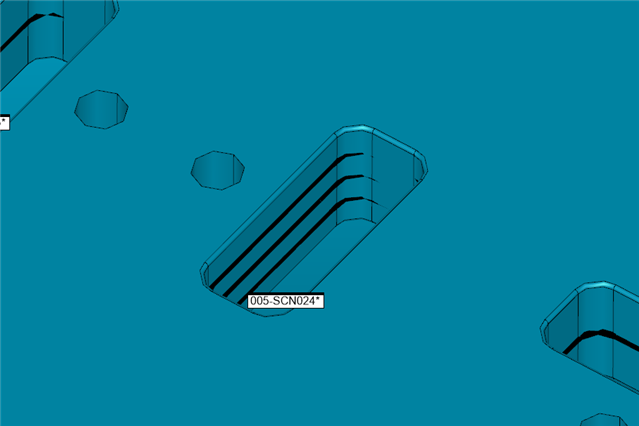

I want to clarify that this question stems from how I’m presenting the results in my report above. I captured each of the scans separately and performed the surface profile callout afterward. I only noticed the discrepancy because, in some cases, I was performing a single line scan in the middle of the feature, while in others, I performed three line scans. This led me to observe a pattern: when combining the three scans for a single callout, the result appeared to average out the deviations, as seen in the combined callout.

After repeating this process about five times on five different rows of holes, the pattern became more apparent. That’s when I stopped to investigate whether there was a difference between calling out scans independently versus combining them. For reference, these were linear scans.

Added more info.

[edited by: NASA_Metrology at 11:01 PM (GMT -6) on Jan 3, 2025]