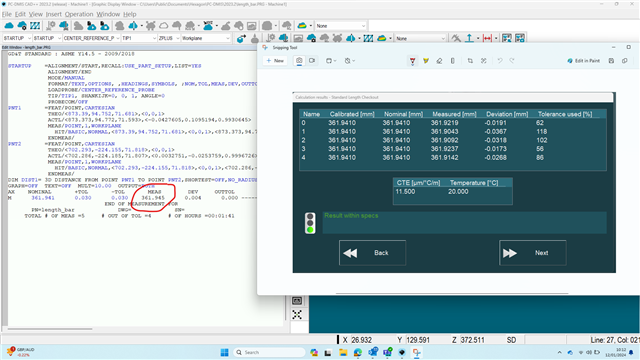

Bizarre behavior. Absolute arm, calibrates fine, length checks, stylus diameter/STDev all fine within RDS software, regardless of length standard or arm orientation (10-20µm at worst).

In PC-DMIS, same arm, same stylus (or master stylus, for that matter), same length standard, length standard reads several millimeters off (3d distance), and is wildly inconsistent. The readings from PC-DMIS probe readouts window were also noted as each hit was taken, and manual calculation confirms bizarre length readings. It's as if PC-PMIS is not interfacing with arm's scales correctly. Once again, RDS software reads fine.

Is there anything we can do short of software re-installation?

Your Products have been synced, click here to refresh