Offline with tactile, I can probe a small radius circle, construct a center point, probe the OD, then dimension the center point to the od subtracting the radius. Comes out good offline. Can I do the same thing with the vision probe?

Attached Files

Your Products have been synced, click here to refresh

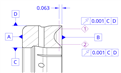

Ok, so my print changed. What the engineer wants to know now is the groove centered in between the ID and OD of this part. C is the ID and D is the OD. At 0.063in from surface B, construct 1 circle on each cone and check the run out of the circles to CD. Pcdmis only lets me choose either C or D and not both.

This is a ring. Attached is my print showing the cross section and the datums. Surface B isn't really there, its showing in the image because its a cross section. That groove is open. So where datum D and B should intersect, its basically a knife edge. Same goes for where C and B would intersect.

Because of this, I had to switch to tactile on my optiv to make D a cylinder. When I dimension runout on the constructed circles, it shows absolutely no deviation. I just want to make sure i'm doing anything wrong.

Plane A is probed, Level Zminus and Z orgin, Cylinder D is probed and XY orgin, nothing to hold rotation.

Dimension cylinder D, show deviation.

Probe C as a circle. Dimension, shows deviation.

Probe 1 cone and then the other.

Construct a circle on each cone.

Dimensions runout for each constructed circle and no deviation on runnout.

Am I missing somthing?

| © 2025 Hexagon AB and/or its subsidiaries. | Privacy Policy | Cloud Services Agreement |