I think what vpt (and me) were hoping for was a way to create an alignment that uses the Xact fit shift. There are all sorts of applications for this. Using the available options in best-fit alignment is not the same, because they do not attempt to fit within a tolerance zone.

A few years old but I haven't found anything using search.

SPH1 =GENERIC/SPHERE,DEPENDENT,CARTESIAN,OUT,$

NOM/XYZ,<0,0,0>,$

MEAS/XYZ,<0,0,0>,$

NOM/IJK,<0,0,1>,$

MEAS/IJK,<0,0,1>,$

DIAMETER/1,1.1

DIM LOC1= LOCATION OF SPHERE SPH1

AX NOMINAL +TOL -TOL MEAS DEV OUTTOL

D 1.0000 0.2500 -0.2500 1.1000 0.1000 0.0000 ------#--

END OF DIMENSION LOC1

DATDEF/FEATURE=SPH1,A

DISPLAYPRECISION/6

FCFLOC1 =POSITION : CIR152_1,CIR152_2,CIR152_3,...

FEATCTRLFRAME/SHOWNOMS=NO,SHOWPARAMS=NO,SHOWEXPANDED=NO

SIZE TOLERANCES/33,DIAMETER,0.375,0.005,-0.005

PRIMARY DIMENSION/POSITION,DIAMETER,0.01,MMC,A,MMC,,

NOTE/FCFLOC1

FEATURES/CIR152_1,CIR152_2,CIR152_3,CIR152_4,CIR152_5,

CIR152_6,CIR152_7,CIR152_8,CIR152_9,CIR152_10,

CIR152_11,CIR152_12,CIR152_13,CIR152_14,

CIR152_15,CIR152_16,CIR152_17,CIR152_18,

CIR152_19,CIR152_20,CIR152_21,CIR152_22,

CIR152_23,CIR152_24,CIR152_25,CIR152_26,

CIR152_27,CIR152_28,CIR152_29,CIR152_30,

CIR152_31,CIR152_32,CIR152_33,,

ASSIGN/V1=GETTEXT("DRF_SHIFTX",1,{FCFLOC1})

ASSIGN/V2=GETTEXT("DRF_SHIFTY",1,{FCFLOC1})

ASSIGN/V3=GETTEXT("DRF_SHIFTZ",1,{FCFLOC1})

ASSIGN/V4=GETTEXT("DRF_ROTATIONX",1,{FCFLOC1})*-1

ASSIGN/V5=GETTEXT("DRF_ROTATIONY",1,{FCFLOC1})*-1

ASSIGN/V6=GETTEXT("DRF_ROTATIONZ",1,{FCFLOC1})*-1

FORMAT/TEXT, , ,HEADINGS, , ;NOM,MEAS, , , , ,

DIM BEFORE= LOCATION OF CIRCLE CIR152_1

AX NOMINAL MEAS

X 10.153721 10.154507

Y -27.402826 -27.405035

Z -8.032519 -8.025360

END OF DIMENSION BEFORE

ALIGN1 =ALIGNMENT/START,RECALL:PREVIOUS,LIST=YES

ALIGNMENT/ROTATE_OFFSET,V4,ABOUT,XPLUS

ALIGNMENT/ROTATE_OFFSET,V5,ABOUT,YPLUS

ALIGNMENT/ROTATE_OFFSET,V6,ABOUT,ZPLUS

ALIGNMENT/TRANS_OFFSET,XAXIS,V1

ALIGNMENT/TRANS_OFFSET,YAXIS,V2

ALIGNMENT/TRANS_OFFSET,ZAXIS,V3

ALIGNMENT/END

DIM AFTER= LOCATION OF CIRCLE CIR152_1

AX NOMINAL MEAS

X 10.151373 10.152161

Y -27.394485 -27.396694

Z -8.041472 -8.034312

D 0.376500 0.377383

END OF DIMENSION AFTER

COMMENT/REPT,

"Xshift: "+V1

"Yshift: "+V2

"Zshift: "+V3

"Rotation X: "+V4*-1

"Rotation Y: "+V5*-1

"Rotation Z: "+V6*-1

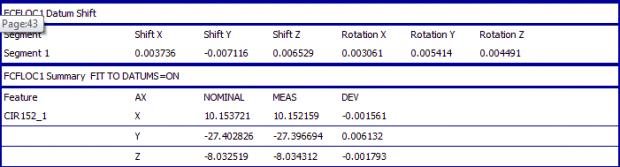

The FCF output with datum shift is:

Using a sphere as the only datum seems to allow all 6 degrees to float. There is some small round-off error due to the numbers being used limited to the current DISPLAYPRECISION (not much).

Now what? Trying to actually use this has me baffled. I'd like to simulate the FCF output having the transformed measured coordinates evaluated against the model nominal values. The BEFORE dim has the nominals I want but the AFTER dim has the measured I want (like the FCF output). Inserting & Recalling alignments, Updating Dependent Commands (answering both yes and no) leaves me feeling like I've found my way into a rabbit hole. Maybe Profile dims behave differently?

I'm aware that some settings may influence the results: Update Dependent Commands (warning), UpdateBelowChangedAlignmentDuringExecution (registry), Ignore CAD to part (F5 settings), Allow Fine Tuning of Alignment (F5 settings). I'd really like to get this working inline without resorting to any type of external automation if possible. Can someone throw me a bone here? There's gotta be a way to get some mileage out of this.