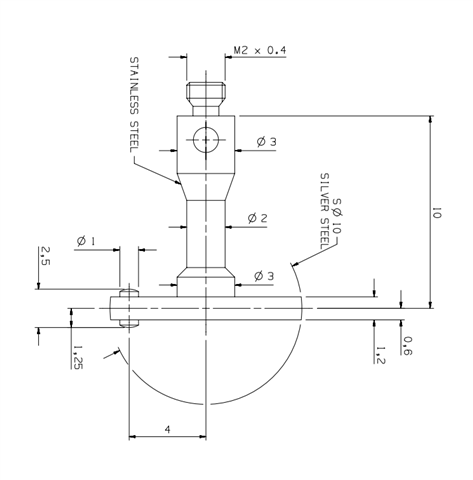

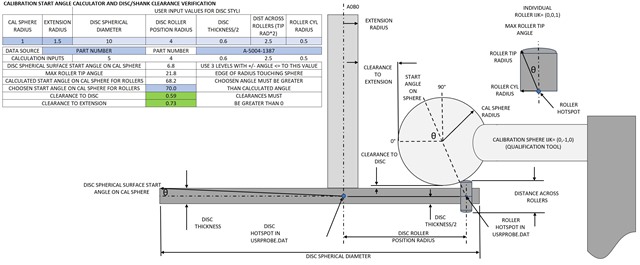

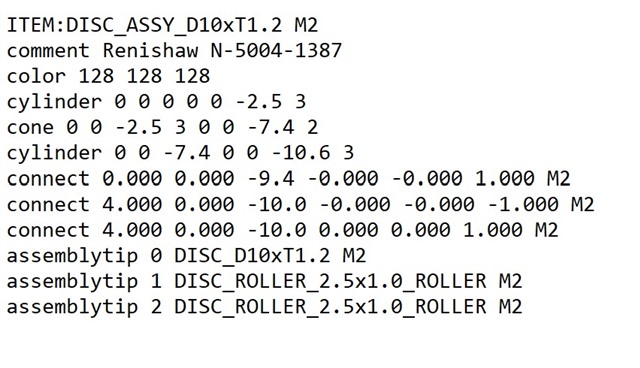

I'm not sure of the proper way to build a disk probe so that I'm able to use the rollers to measure groove width. I was told to add some offset point to the routine but that's not working. There has to be a way to build the probe so that the rollers are on there right? ive never built a probe from scratch so I may be lost in the procedure or even the capabilities. I have included a dwg of the disk to help.