Your Products have been synced, click here to refresh

Your Products have been synced, click here to refresh

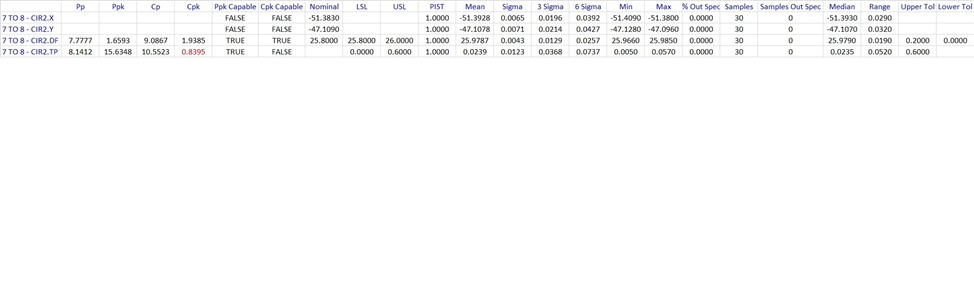

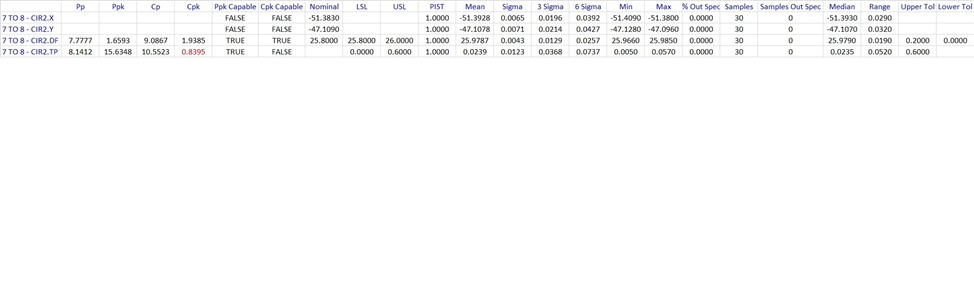

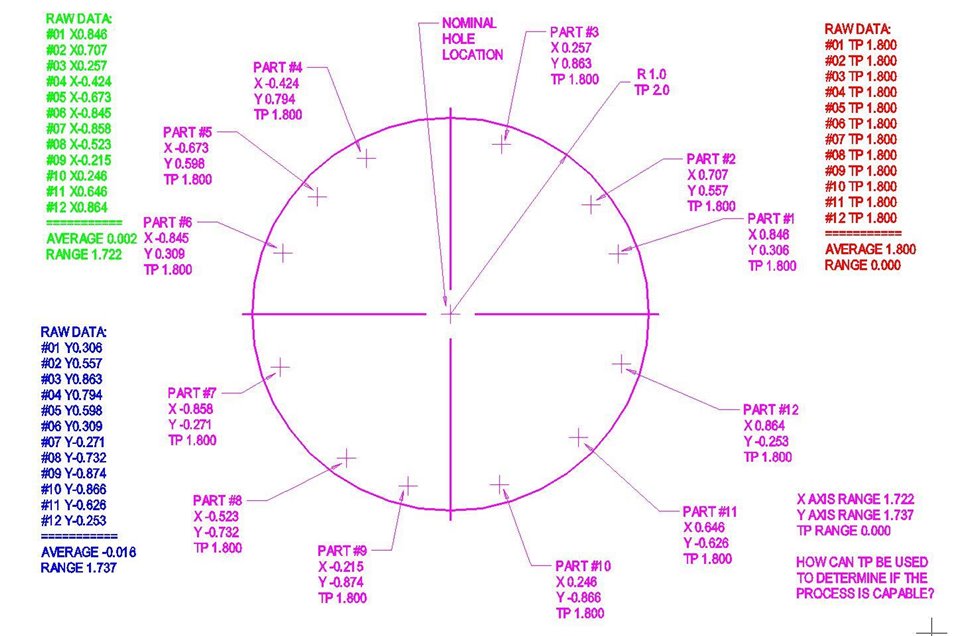

you shouldn't do SPC on position of holes. You will NEVER get a good result, even if it shows great.

| © 2025 Hexagon AB and/or its subsidiaries. | Privacy Policy | Cloud Services Agreement |