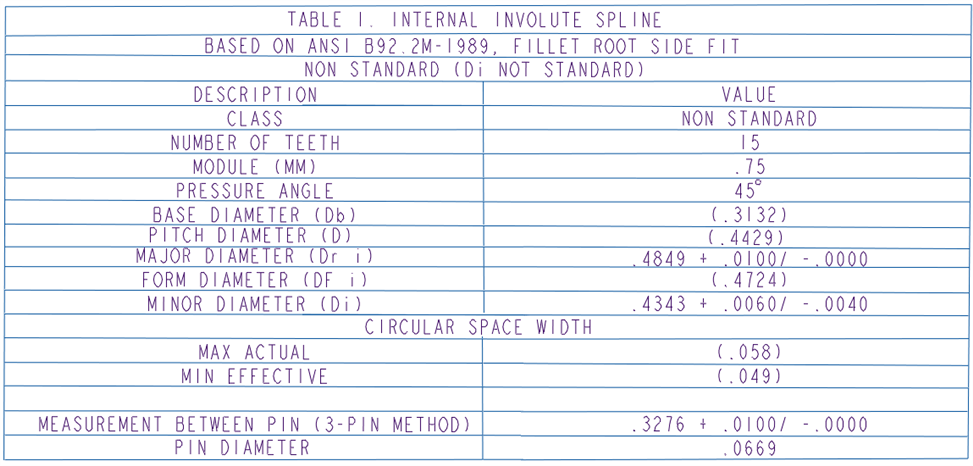

For those of you who have ordered Go/Nogo gages for splines... how do you confirm they are made correctly? Do you all have any information you can pass along to help me understand how to compare customer print with gage maker go/nogo print? I don't know a whole lot about spline gages or splines in general and would like to understand them a little better. I attached the part print for the spline of the part. Now how would i take this and determine the sizes/specs of a Involute spline go and nogo gage.

Thanks in advance