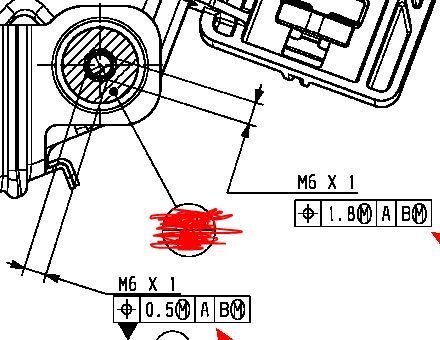

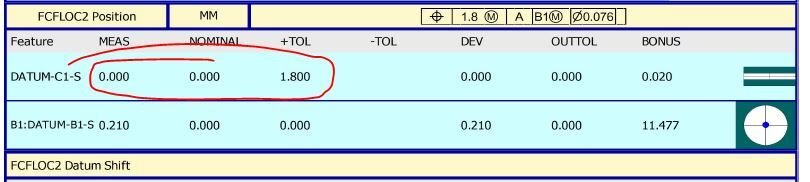

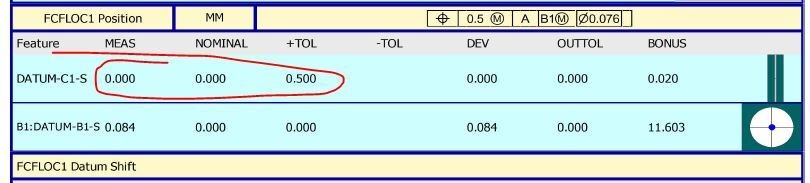

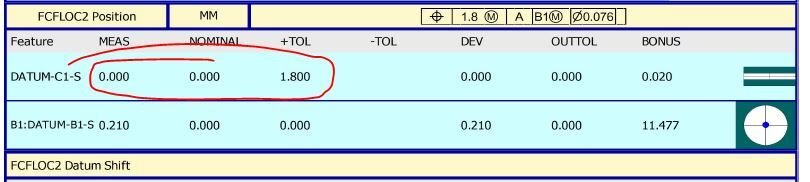

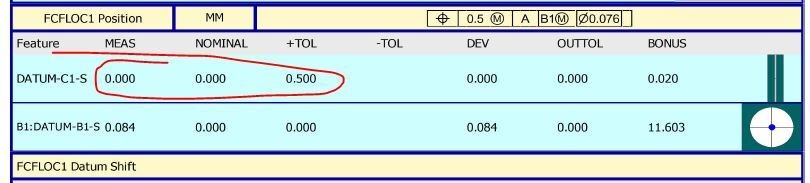

but my report shows these results:

Why is it always 0? There are several TP like these in my drawing and all show the same results, 0.

Please help!!!

Your Products have been synced, click here to refresh

| © 2024 Hexagon AB and/or its subsidiaries. | Privacy Policy | Cloud Services Agreement |