Hello everyone,

I need advice...

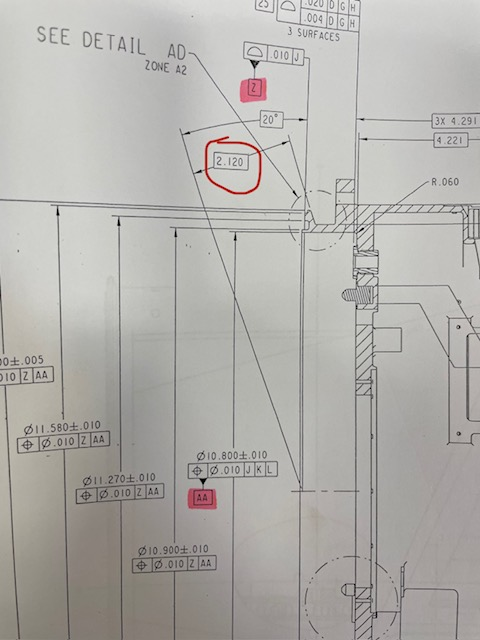

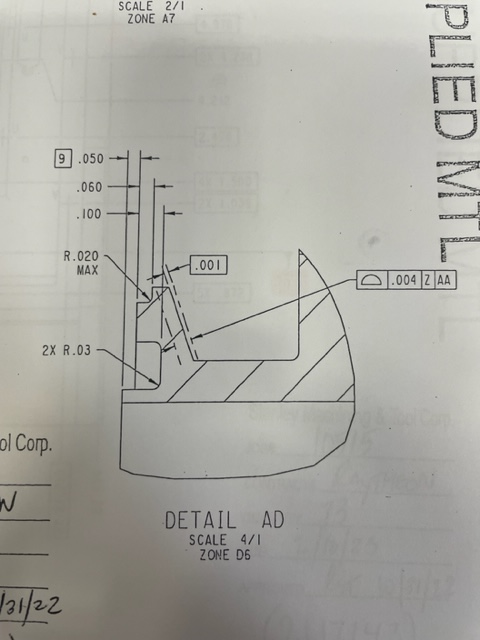

The operator says that the parts are good, the angle is perfect (20 degrees), I get a different result on the CMM after measuring.

Am I making some mistake? I only have one year of experience...

I don't like CON1 (position on the x-axis). CON1 is made up of 8 points to see only the average of the angle and i location (print doesn't call out)).

I would like to add codes but i don't know how to do it...

This is how i created:

WORKPLANE/ZPLUS

MOVE/POINT,NORMAL,<17.88762,5.57913,-0.19795>

TIP/T1A90B90, SHANKIJK=0.99979, -0.02011, -0.00449, ANGLE=-90.78014

PNT14 =FEAT/CONTACT/VECTOR POINT/DEFAULT,CARTESIAN

THEO/<5.64,0,-0.225>,<0.3420223,0,-0.9396918>

ACTL/<5.63419,0.00011,-0.20894>,<0.3420223,0,-0.9396918>

TARG/<5.64,0,-0.225>,<0.3420223,0,-0.9396918>

SNAP=NO

SHOW FEATURE PARAMETERS=NO

SHOW CONTACT PARAMETERS=YES

AVOIDANCE MOVE=NO

SHOW HITS=YES

HIT/BASIC,<5.64,0,-0.225>,<0.3420223,0,-0.9396918>,<5.64,0,-0.225>

ENDMEAS/

PNT15 =FEAT/CONTACT/VECTOR POINT/DEFAULT,CARTESIAN

THEO/<5.8,0,-0.18>,<0.3420223,0,-0.9396918>

ACTL/<5.78983,0.00012,-0.15185>,<0.3420223,0,-0.9396918>

TARG/<5.8,0,-0.18>,<0.3420223,0,-0.9396918>

SNAP=NO

SHOW FEATURE PARAMETERS=NO

SHOW CONTACT PARAMETERS=YES

AVOIDANCE MOVE=NO

SHOW HITS=YES

HIT/BASIC,<5.8,0,-0.18>,<0.3420223,0,-0.9396918>,<5.8,0,-0.18>

ENDMEAS/

LIN4 =FEAT/LINE,CARTESIAN,UNBOUNDED,NO

THEO/<5.80559,0,-0.1782>,<-0.9626509,0,-0.2707456>

ACTL/<5.78964,0.00012,-0.15191>,<-0.9388199,-0.000083,-0.3444084>

CONSTR/LINE,BFRE,3D,PNT15,PNT14,,

OUTLIER_REMOVAL/OFF,3

FILTER/OFF,WAVELENGTH=0

WORKPLANE/YMINUS

DIM ANGL3= 2D ANGLE TO LINE LIN4 FROM XAXIS ,$

GRAPH=OFF TEXT=OFF MULT=1.00 OUTPUT=BOTH

AX NOMINAL +TOL -TOL MEAS DEV OUTTOL

A 20.00000 0.00000 0.00000 20.14569 0.14569 0.14569 -------->

A5 =ALIGNMENT/START,RECALL:STARTUP,LIST=YES

ALIGNMENT/LEVEL,ZPLUS,PLN2_Z

ALIGNMENT/ROTATE_CIRCLE,YMINUS,TO,CYL1_AA,AND,PNT2,ABOUT,ZPL US

ALIGNMENT/TRANS,ZAXIS,PLN2_Z

ALIGNMENT/TRANS,XAXIS,CYL1_AA

ALIGNMENT/TRANS,YAXIS,CYL1_AA

ALIGNMENT/ROTATE_OFFSET,-20,ABOUT,YPLUS

ALIGNMENT/END

WORKPLANE/XPLUS

PLN4 =FEAT/PLANE,CARTESIAN,OUTLINE,NO

THEO/<0,0,0>,<1,0,0>

ACTL/<0,0,0>,<1,0,0>

CONSTR/PLANE,ALIGN,WORKPLANE

PNT11 =FEAT/POINT,CARTESIAN,NO

THEO/<0,0,-1.74828>,<-0.9971964,0,0.0748284>

ACTL/<0,-0.00032,-2.13663>,<-0.9999968,-0.000083,-0.0025427>

CONSTR/POINT,PIERCE,PLN4,LIN4

DIM LOC4_LIN4= LOCATION OF POINT PNT11 UNITS=IN ,$

GRAPH=OFF TEXT=OFF MULT=1.00 OUTPUT=BOTH HALF ANGLE=NO

AX NOMINAL +TOL -TOL MEAS DEV OUTTOL

X 0.00000 0.01969 0.01969 0.00000 0.00000 0.00000 ----#----

Y 0.00000 0.01969 0.01969 -0.00032 -0.00032 0.00000 ----#----

Z -2.12000 0.00200 0.00200 -2.13663 -0.01663 0.01463 <--------

END OF DIMENSION LOC4_LIN4

Attached Files