Hey all,

We've got some bright Machinists here that are tired of having the CMM programmer manual align their parts every few months. We get a few repeat jobs once every 6 months or so, and by that time either probe calibration, machine settling or by some other factor I'm not aware of our programs will need a new manual alignment. Afterwards, we unmark these features and let the job run in DCC mode. (sidenote, my hunch is that the manual alignment feature's measured coordinates are married to the previous probe alignment, so after a new alignment they don't 'match' the expected coordinates for DCC mode)

Anyways here is my question/discussion; What are the pros/cons of using a manual alignment vs a know x,y,z position for part programs?

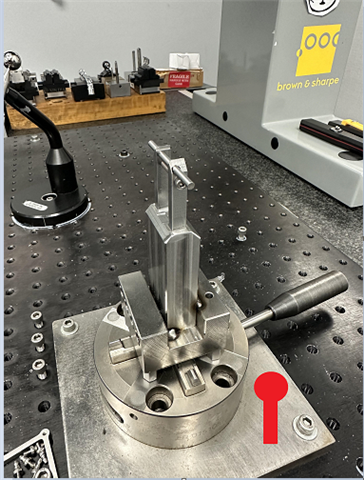

I don't have a good answer for rebuttal to our machinists, and I'm starting to wonder if some of our programs would be better off with hard-coded workpiece offsets. We use an Erowa chuck with custom fixturing for 70% of our jobs, so these parts are highly repeatable.

What are your thoughts?

Your Products have been synced, click here to refresh