Before studying mechanical engineering, the author trained as an industrial mechanic and worked in quality assurance for injection moulded components. He therefore knows that there are often false statements in this area, such as the sample size.

Consider an injection mould with 4 cavities. Now some people assume that this would be a 4-cavity subgroup. But that is wrong! Only 4 components from 4 cavities have been produced at the same time!

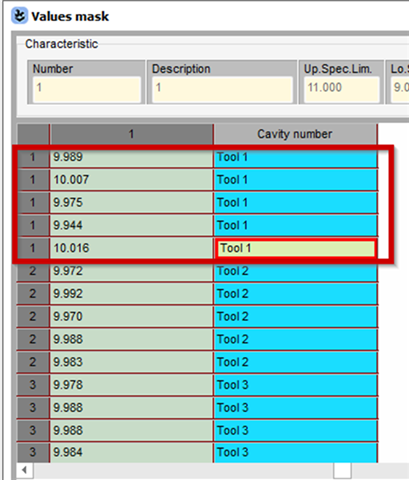

If this production process is now repeated 5 times, you only have a subgroup of 5 per cavity.

In most cases, the measured values are recorded in a characteristic, but still follow the rules per subgroup: no change in additional data within a subgroup

As cavities cannot be controlled separately in many cases (the author's knowledge here is 20 years old, there may already be tools today where temperature / pressure and other parameters can be controlled per cavity), the measured values are usually recorded in one characteristic.