How to handle with outliers is an ongoing issue. Whether as a request or as a question to the helpdesk, because it is seen as a problem that the evaluation has "so few" measured values. Therefore, before the outlier treatment is actually performed, it is up to the customer to decide whether and how to perform it. This is a multi-faceted and complex issue, which is already covered in detail in the evaluation strategy manuals, but the focus here should be on general understanding. This article may need to be read iteratively several times. And it is recommended that this is discussed in the project or in a training session.

Outliers in the machine and the process capability analysis

The technical possibilities are the same in both modules, the Sample Analysis and the Process Capability Analysis. But the philosophical approach is different.

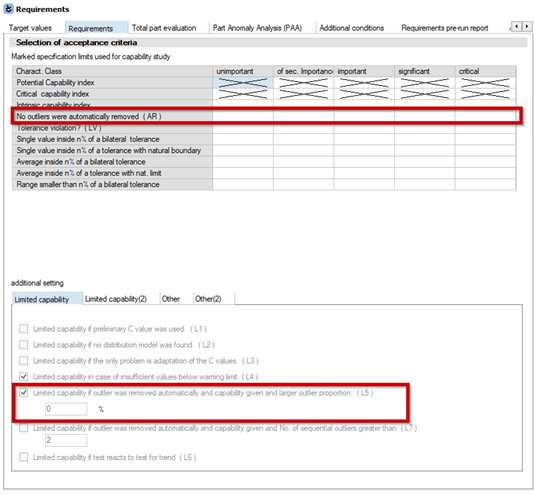

Outliers in process capability analysis are perfectly normal for many customers. Continuous data flow, automatic recording mechanisms, problems with incorrect measured values can occur anywhere. But not when it comes to sample analysis, to the analysing machine capabilities! A machine capability should be performed under control! So can there be outliers? Not really. There is a reason why the possibilities are still there: IF outliers are found, i.e. it must be assumed that no control of the data recording has taken place, you can then define in the machine capability that, no matter how good the process would still be towards the end, the process is output as conditionally capable or even as not capable BECAUSE outliers were found.

Types of outliers

A distinction is made between:

"outliers based on limit values" and "mathematical outliers"

And

"Automatic outlier consideration during evaluation" and "manual outlier consideration"

Outliers based on limit values

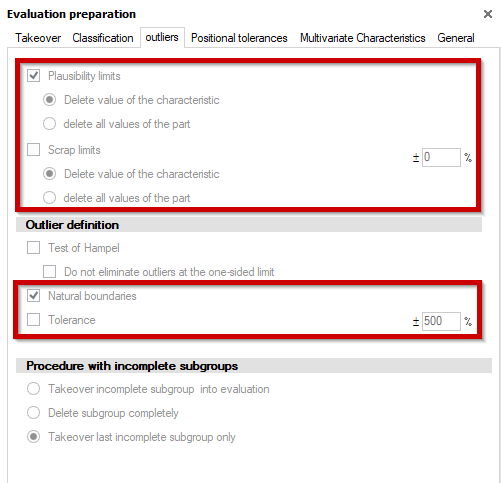

A value 'x' is above or below the specified limits and is therefore defined as an outlier. Various options are available in the 'Preparation' tab of the strategy.