Although the two PreRun methods originated in the North American market, they are increasingly being used worldwide before the actual machine capability analyses.

What the purpose of those "PreRun" Studies?

The idea is simple: for the "Machine capability study" typically 50 parts from the new machine are manufactured and measured. The idea is now to check beforehand whether the new machine is setup and targeted correctly, before potentially "wasting" the parts produced fir the capability study. This is where PreRun Studies s come in.

The first part is directly measured and evaluated with the "1-Part PreRun".

The assessment here is based solely on the location of the first part made to see if it is within a certain tolerance range and as to have an indication whether a machine targeting move is required.

After a potential machine adjustment, the first part is produced after the move checked again via "1-Part-PreRun" until all If all values are within the expected tolerance range.

Then, the first "subset" of 5 parts is then produced, measured and evaluated with the "5-Part PreRun".

Various graphs and reports are available for this and the "Results" tab.

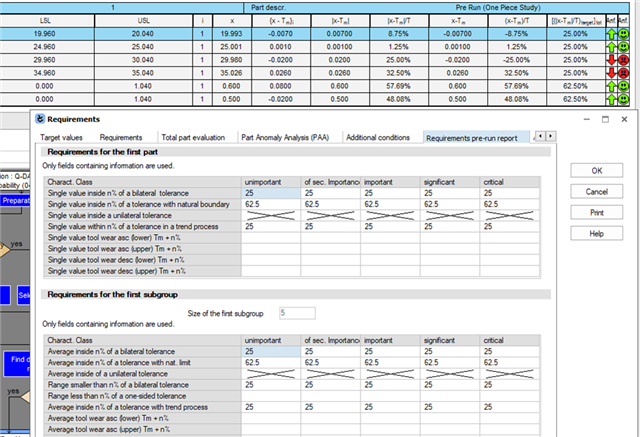

The respective evaluations have their own "smiley" and, as always, the requirements are anchored in the evaluation strategy.

The requirements for the first subgroup / 5 parts PreRun refer to location of the average of the 5 parts being with a certain tolerance range and now in addition, the range of the first 5 parts is checked for being n% of the tolerance.

The percentages are setup in the "Requirements Pre-Run report" tab in the evaluation strategy. The percentages vary depending on company specific rules and are mainly based on experience. There is not much statistics behind them. The percentages are empirical values that have worked well in the past.

There is no "guarantee" that the machine capability study requirements will be met later - but should increase the chances.