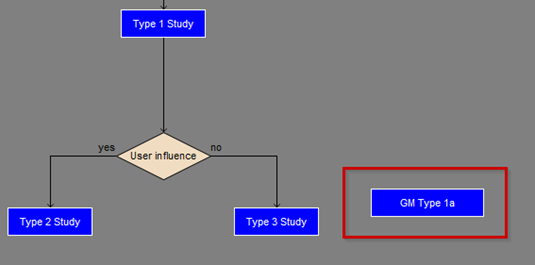

"GM Type 1a" does not exist in most strategies and would first have to be activated as a procedure.

As this procedure comes from "GM", one of the GM strategies in which this is activated could be selected for tests.

A Type 1A is a special "Type-1 Study" for "Deviation measurements". Briefly mentioned using the example of a screwdriving process:

The screwdriving process itself is a "destructive" process. The manufacturing process is simultaneously the measurement process and cannot be repeated. So how is the precision determined?

With type 1A, the measurement is carried out against a reference rather than the real screwdriving process. Against a calibrated load cell. This gives each "measured value" its "reference". The display on the measuring device against the display on the load cell.

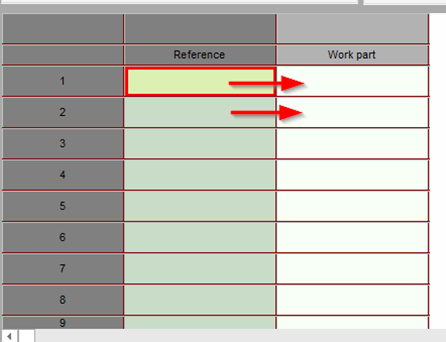

Therefore, only the number of "value pairs" must be specified on the characteristics mask for the measurements:

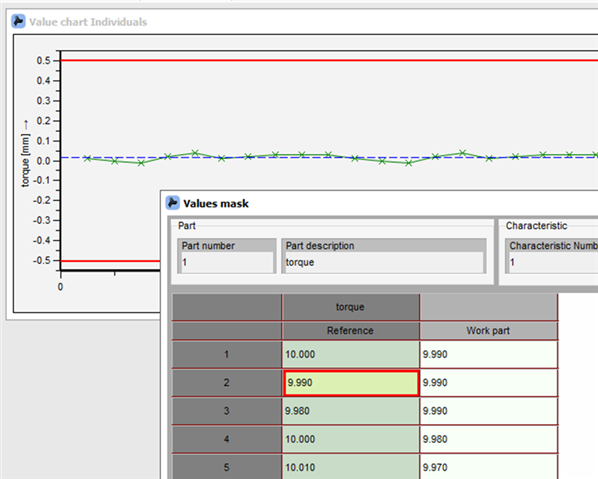

These "Deviation measurements" are entered in pairs in the values mask, in each case the specification in the reference and the measured value on the device:

Basic Analysis

After evaluation, the value chart shows the variations of the measurements, based on the average of the reference measurements.

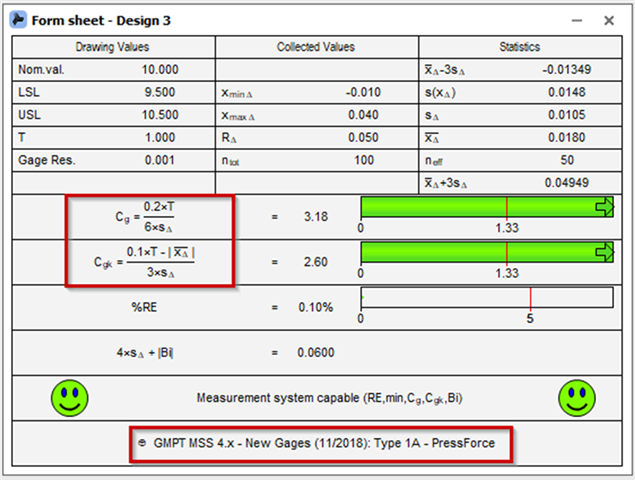

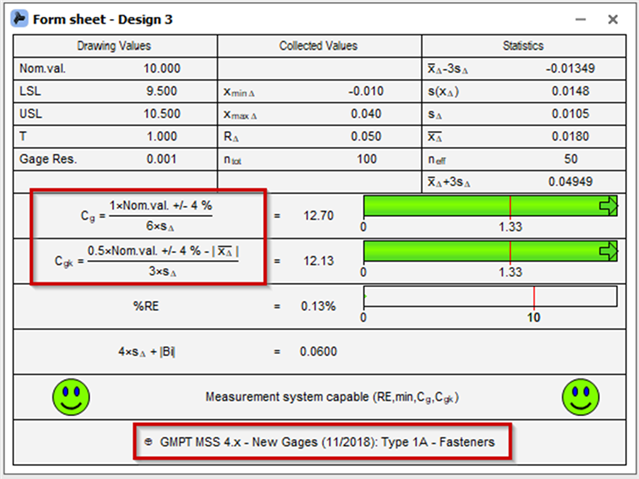

The evaluation itself is a classic Cg / Cgk, but with a special formula for "GM Type 1a".

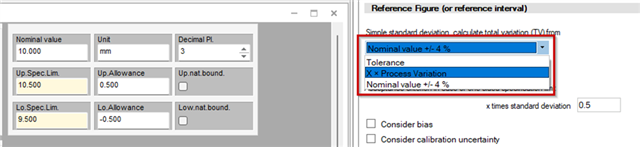

The strategy and the possible reference values must be taken into account here. For "GM Type 1a", "+-4% of the nominal value" is also available as a reference:

When using the tolerance as a reference value, the specification limits are mandatory information on the characteristics mask; when using the reference value "nominal size +-4%", only the nominal size is important.

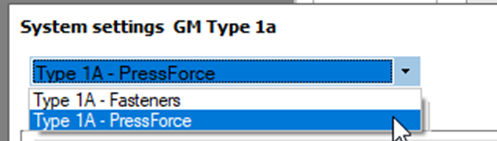

In the GM strategies, a distinction is made here between "Fasteners" and "PressForce" with sub-strategies:

On the form sheet, depending on the sub-strategy selected, the calculation can be seen with different reference values in the Cg/Cgk formula: