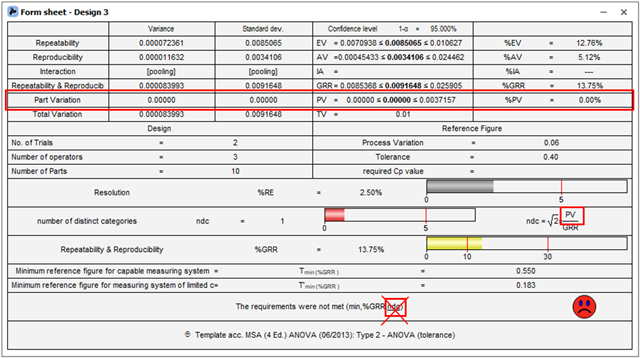

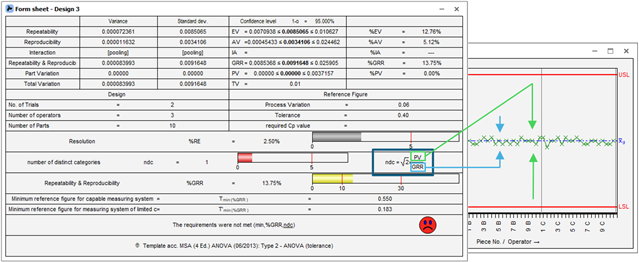

Many companies face a problem after an MSA audit: measurement systems that were previously classified as capable according to the %GRR ratio were unable to meet the requirements of the additional ndc ratio.

Table of Contents

For statistical data analysis, not only the data generated by the manufacturing process is important, but also the reliability of the measurement process. Measurement System Analysis (MSA) is used to investigate how much variation in results is caused by the measurement equipment.

In MSA the Gage R&R (Repeatability & Reproducibility) is a method of determining how good a measurement system is at measuring a given measurement task. With Gage R&R it is possible to analyse what proportion of the data comes from the measured parts and what proportion from the measurement system.

The ndc is one of the criteria used to evaluate the measurement system's capability by indicating the sensitivity of the measurement system. It indicates the “Number of Distinct Categories” that can be clearly and reliably distinguished by the measurement system used.

The aim of this analysis is to achieve repeatability and reproducibility both inside and outside of the tolerance range. This means that not only the good parts but also the bad parts should be included in the

The challenge with ndc

With the ndc, the MSA user is forced to use parts that are spread over the entire tolerance range and not only within the part variation!

The aim of the ndc is to determine repeatability and reproducibility, not only in the area of actual part variation. The aim is to ensure that not all components are at the same tolerance location. Rather, the ndc should be determined over the entire tolerance range and, in addition, the repeatability and reproducibility should be guaranteed in all tolerance situations.

According to the MSA, a minimum number of distinguishable measurement classes is required for meaningful process control. This is set at 5.

The "inventor" of ndc wanted to ensure that parts were not all measured within the same tolerance range. The process control calculation, which typically consists of 10 representative parts of the GRR study (Type-2 Study), should cover the entire tolerance range between the upper and lower specification limits. The problem with this way of thinking is that it can happen that no bad parts are produced and therefore the range cannot be covered. In addition, there has been no definition of a calculation formula. Therefore, different MSA requirements lead to different considerations and formulas.

Consideration of the ndc in different MSA editions

The evaluation strategies based on the MSA 2nd edition have calculated the ndc with reference to the tolerance range. This means that the small variation in repeat measurements was related to the tolerance range. The variation is related to the tolerance range. If the variation is small, the calculated ndc doesn't make sense.

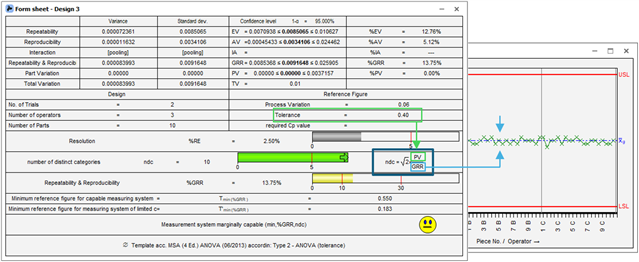

So AIAG made improvements. From the 3rd edition of the MSA, the evaluation strategies refer to the "part variation", the variation across all measured values.

However, this approach means that measurement systems that are classified as capable according to the %GRR ratio will not be able to meet the requirements of the ndc ratio. Therefore, an additional option has been created in the evaluation strategy.

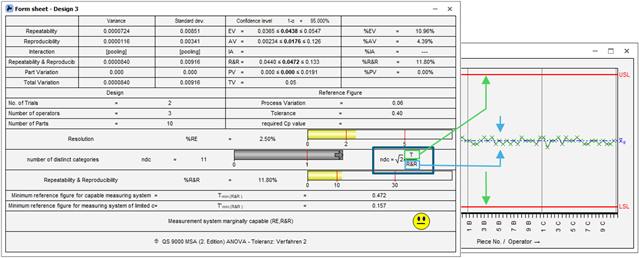

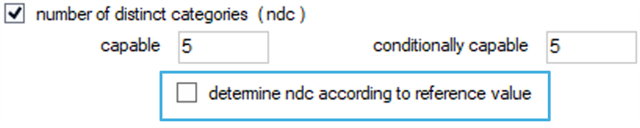

When this option is enabled, the ndc is calculated using the tolerance. Enabling this option will allow tolerance to be applied to ndc only. There is no change to the %GRR calculation, but the NDC is now classified as capable.

Is the ndc usefull in practice?

Yes and no!

The aim of ndc/MSA analysis is to achieve repeatability and reproducibility both within and outside the tolerance range. However, it is not always possible to produce parts within the full tolerance range. Given the mathematics behind the ndc calculation, the variation is required.

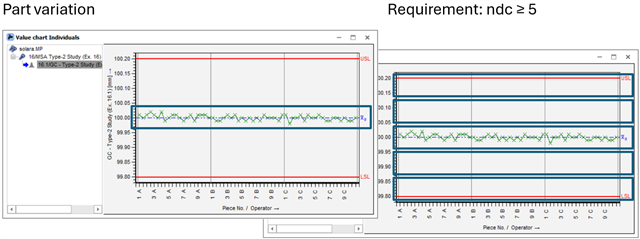

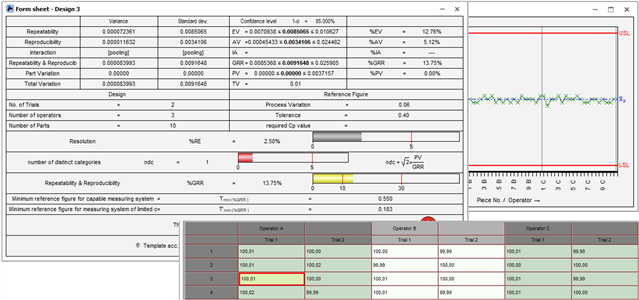

Consider example “Test_16.dfq” from the delivery.

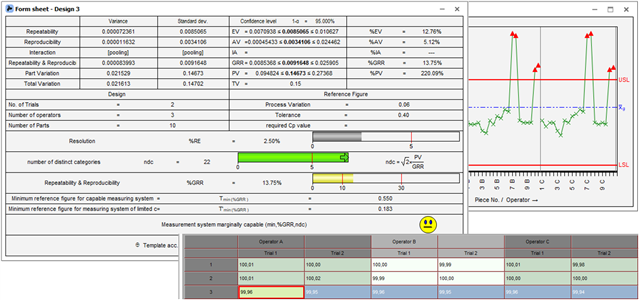

Suppose the third part to be measured is manipulated so that it is only few tenths further away, but has the same repeatability and reproducibility.

This manipulation leads to the calculation of a very high ndc. But manipulation is to be considered as "fraud".

Manipulation is not allowed. Calculation using “default” evaluation strategies will result in an NDC that is not capable. Capable ndc is then only possible when the part variation is calculated using the tolerance. This makes no sense, but the ndc is required. So why use ndc?

Even if it’s not technically possible to produce parts within all 5 classes of the ndc, the person in charge of the process should at least try to have some variation. For example, stamping processes cannot produce parts within the full tolerance range. So, two parts from the early shift, two from the middle shift, over weeks, months, etc. A sample collection here is not to comply with an NDC. Rather, to see if the measuring device is still good in case of limit/fringe/borderline cases.

So, NO to ndc as a requirement.

And YES to ndc as information for the person in charge of the process. To assess measurement uncertainties and to recognize and consider measuring device limits. The only accurate way to do this is to use an evaluation strategy from the MSA 3rd or 4th edition, where the part variation is used as a reference for the ndc.