In the signal detection method, a "discretized characteristic" is first measured continuously on many components before the operators test these components with a gauge.

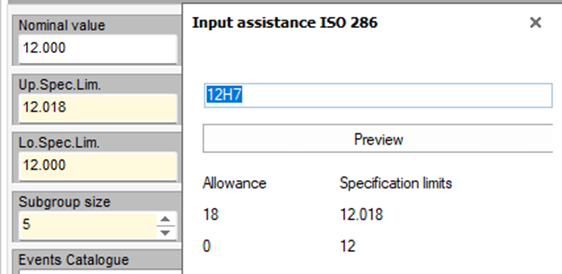

As an explanatory example, a bore with the diameter "12 H7" is to be tested.

This diameter could be measured:

For production monitoring, however, this is "only" checked with a limit plug gauge:

In order to better understand the sampling and the structure of the values mask, the analysis carried out later must be explained in advance.

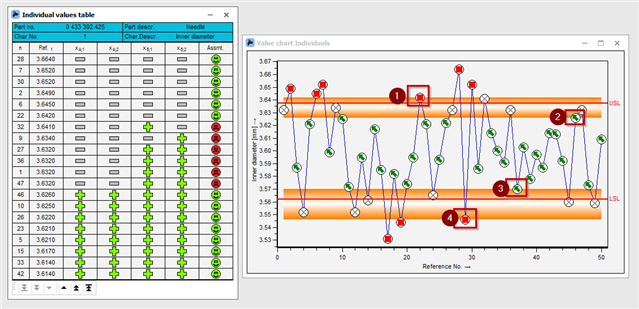

As the term "signal detection method" suggests: The tolerance range from top to bottom is used to check when:

- the last matching rejection

- the first matching acceptance

- the last matching acceptance

- the first matching rejection

were determined. The term "disagreement" here means that either the operators made different statements, or the operators disagreed with the reference value.

The area in between, and shown as orange bars in the value chart, is the "grey scale range". The "R&R" of the signal detection method in % of the tolerance width reference value.

Sampling

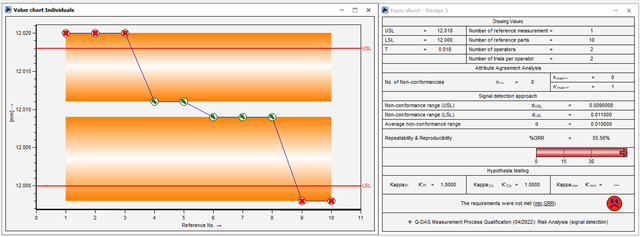

But what does this mean for sampling? The person responsible for this analysis must select components that cover and exceed the entire tolerance range! And the components must be so close to the specification limits (inside and outside) that a qualified statement can be made in these areas.

This is because if there are no "reference values close to the specifications", the grey scale range becomes so large until measured values are available again:

Data Collection

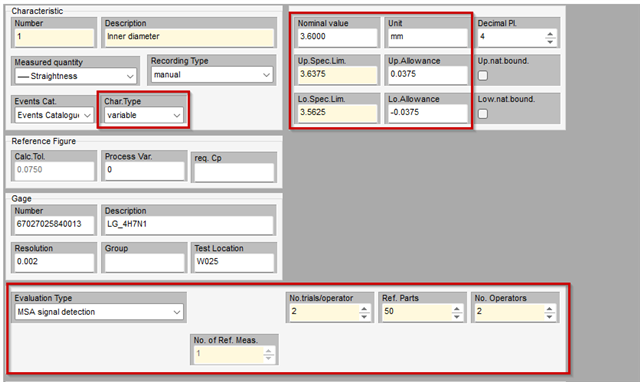

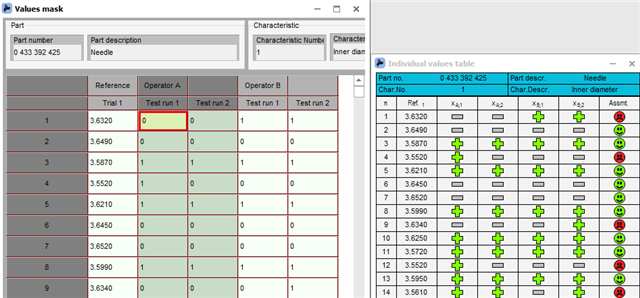

In addition to the specification limits, the number of reference measurements (several reference measurements can be specified) as well as the number of operators, number of test objects and repeat measurements must be specified on the characteristics mask. The "Characteristic type" MUST remain set to "variable", as the measured values recorded are also variable.

The operator's decisions are indicated on the values mask next to the reference value(s). 0 stands for "bad", 1 stands for "good"

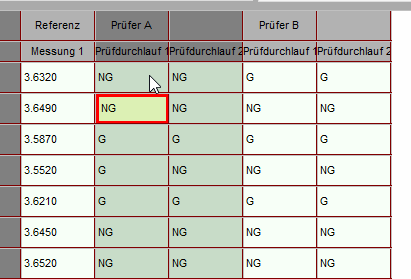

In solara.MP, you can make the setting here (under Setup data recording standard) that other outputs are used on the values mask instead of 0 and 1

Despite the setting, the entry can still be made with 0 and 1, the entries are then rewritten and only displayed differently.