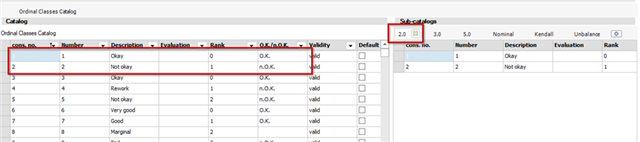

This procedure involves discrete characteristics where there is no "reference measured value", but the reference itself is also a "decision". The "measured values" are therefore entries from the ordinal classes catalogue, which the end customer must set up here (if the standard entries are not sufficient).

Each ordinal "level" is specified here and summarized in sub-catalogues. Each entry must have a rank and an indication of whether its selection is good/bad or unrated:

When taking samples, the same rules apply as for "MSA Signal Detection" - samples of all variants must be taken, borderline components where the operators would possibly make different statements, components where the analysis should really determine the "quality" of the statement of this ordinal test.

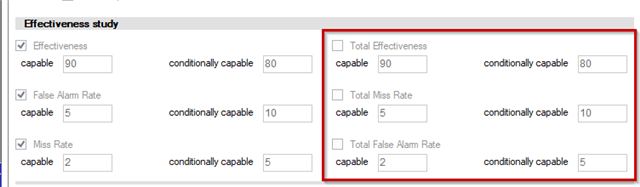

For this "How-to", the author has decided that the analysis will be carried out according to "effectiveness". (Info: no "Q-DAS strategy" has these requirements so far, as this method is newer than the creation of the strategies).

Brief explanation of this decision: None of the possible calculations is "bad". But the user, the evaluator, should be given information that goes beyond the smiley. Therefore, the Kappa methods and effectiveness are compared here before data recording and mask structure are explained.

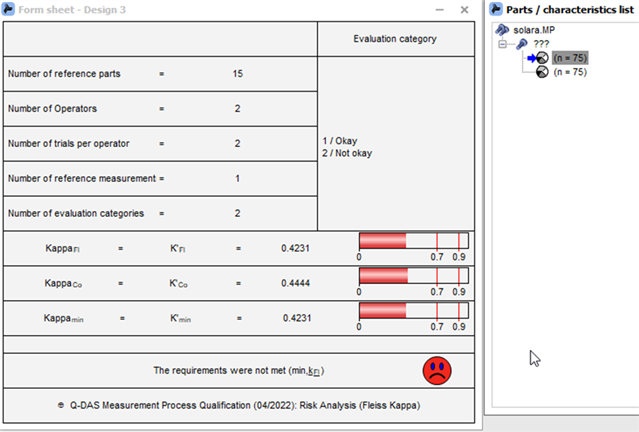

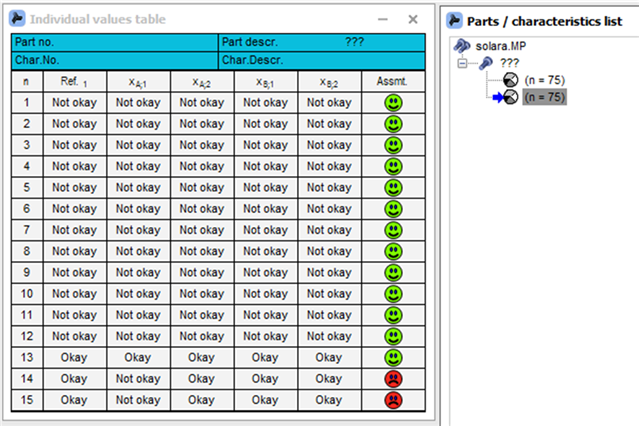

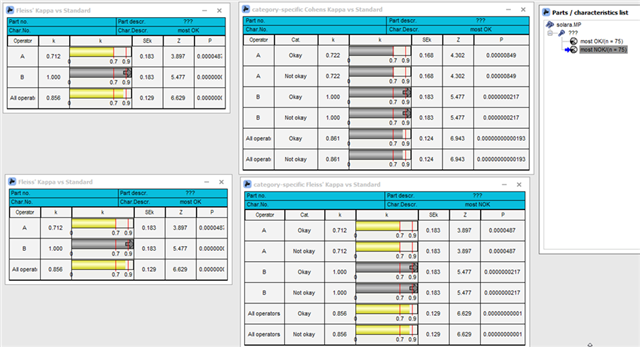

Two characteristics are tested according to Kappa. Both characteristics calculate the same values:

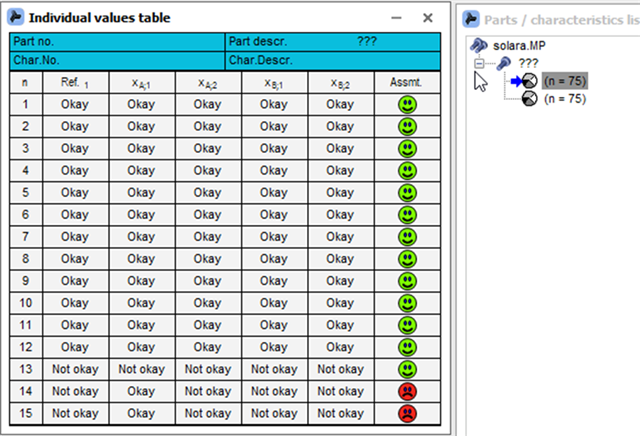

However: a large number of "OK" parts were checked for the first characteristic, non-conformities are only in the last 3 components, which were "Not OK" according to the reference.

The second characteristic is completely opposite:

The Kappa value, however, is identical, and only the category-specific presentation could still show a difference:

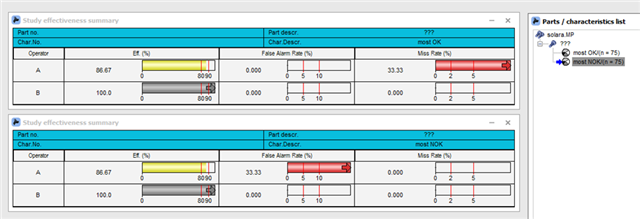

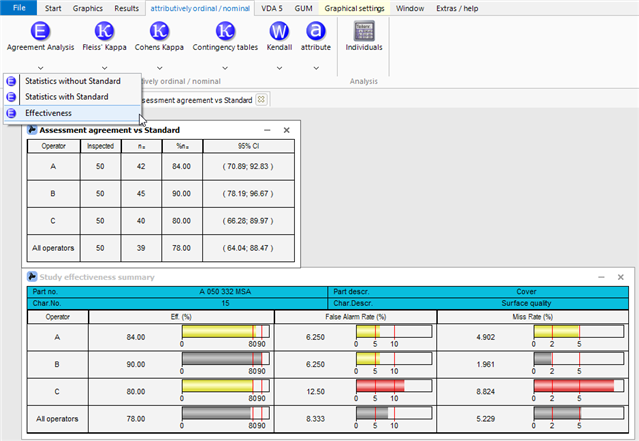

The new options for calculating effectiveness show a different picture here:

Even if the degree of effectiveness is identical: With the requirements of False Alarm Rate and Miss Rate, the problems can be better considered:

False alarm rate: As the name suggests: false alarms. Good components are thrown away because operators wrongly define them as bad. This is an economic loss for your own company

Miss rate: This is now the proportion of bad components that are delivered to the end customer because they were wrongly defined as good. Irrespective of the economic loss, this can result in harm to life and limb, depending on the type of components inspected.

For these reasons, this "How to" will focus on analysing according to effectiveness. The special case of nominal characteristics is ignored. Nominal characteristics are also "levels", but without a statement of quality (good/bad/unrated). An example of this would be the levels "red/yellow/green/blue". None of these are good or bad. Here, effectiveness is only a conditionally good analysis, failure rate and false alarm rate are irrelevant.

Data recording

Before data recording, the catalogues must be defined. Various sub-catalogues are available; if these are not sufficient, new entries and new sub-catalogues can be defined.

The most important definition in the catalogues: How many levels are there? Only good/bad? Then the delivered 2-level catalogue would be sufficient. The following example assumes a 2-level sub-catalogue (good/bad).

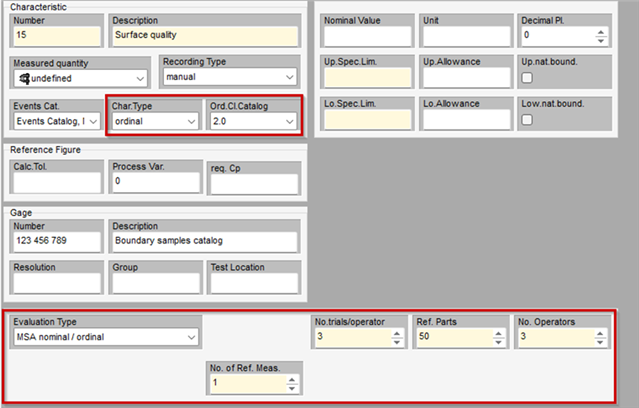

In addition to specifying the sub-catalogue to be used, the only important information on the characteristics mask is how many components have been tested by how many operators and how often. The characteristic type should remain set to "ordinal". (For other forms of analysis for nominal characteristics, you can switch over).

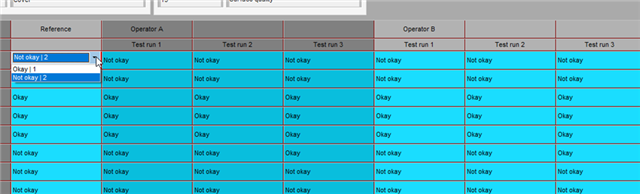

The reference and the inspections are selected by the user from the catalogue on the values mask. The number of entries that can be selected is limited by the selection of the sub-catalogue on the characteristics mask:

Basic Analysis

The effectiveness graphic is located alongside all other graphics for attributive analyses on the tab created specifically for this purpose.

From version 15 (2024.1), the overall calculations can also be set as a requirement in addition to the individual requirements (worst case consideration).