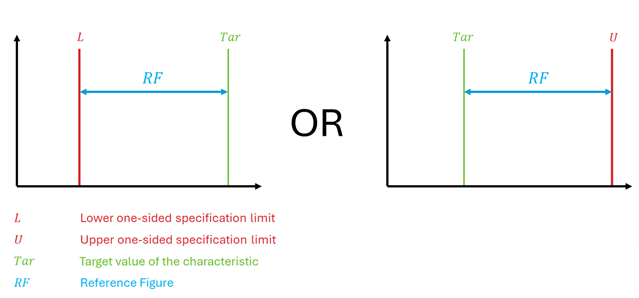

There is no tolerance for a one-sided specification limit. For this situation, the VDA5 suggests replacing the tolerance with a so-called reference figure. Three types of reference figures are available in the solara.MP software.

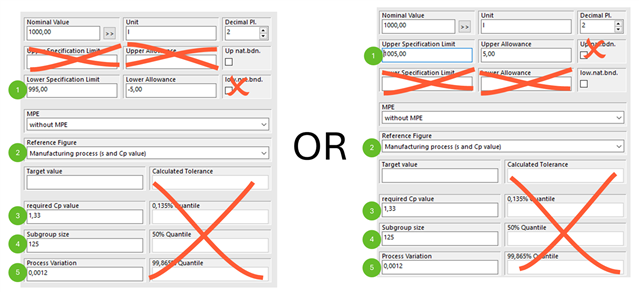

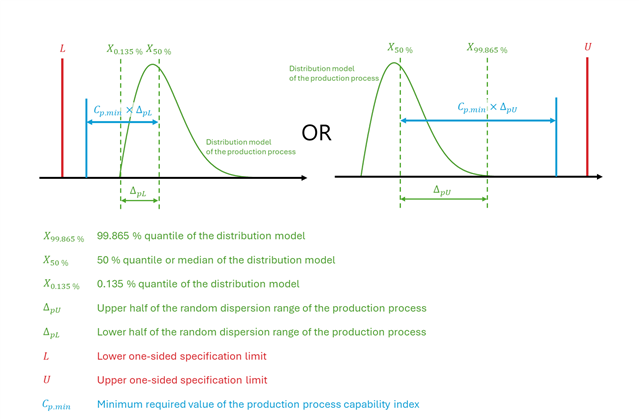

1. Reference figure "Manufacturing process (s and Cp)"

In this case we assume normal distributed production process data and the user must provide in the "Master data" characteristics mask ...

- EITHER the upper limit OR the lower limit.

- The Reference Figure "Manufacturing process (s and Cp value)".

- The minimum required capability index Cp of the manufacturing process.

- The total sample size of the data which has been used to calculate the standard deviation (our next field marked as '5').

- The calculated value of the standard deviation of the manufacturing process.

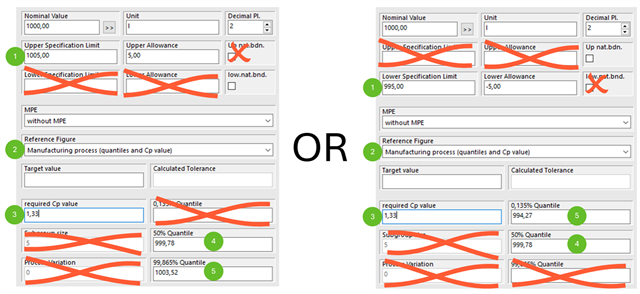

2. Reference Figure "Manufacturing process (quantiles and Cp value)"

In this case we assume not normal distributed production data and the user must provide in the "Master data" characteristics mask ...

- EITHER the upper limit OR the lower limit.

- Reference Figure "Manufacturing process (quantiles and Cp value)".

- The minimum required capability index Cp of the manufacturing process.

- The 50 % Quanile of the distribution model which has been fitted to the manufacturing process data.

- If the upper limit is given, then provide only the 99.865 % quantile of the distribution model which has been fitted to the manufacturing process data.

If the lower limit is given, then provide only the 0.135 % quantile of the distribution model which has been fitted to the manufacturing process data.

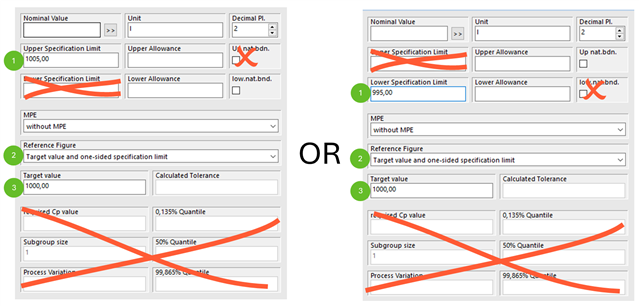

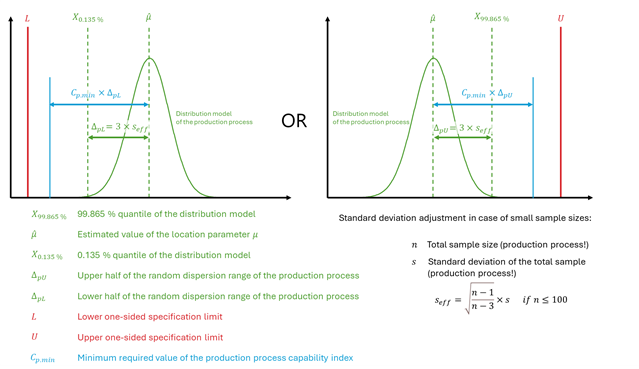

3. Reference Figure "target value and one-sided specification limit"

In this case we assume arbitrary distributed production data and the user must provide in the "Master data" characteristics mask ...

- EITHER the upper limit OR the lower limit.

- Reference Figure "Target value and one-sided specification limit".

- The target value of the characteristic.