There is no tolerance for a one-sided specification limit. For this situation, the VDA5 suggests replacing the tolerance with a so-called Reference Figure. Three types of Reference Figures are available in the solara.MP software.

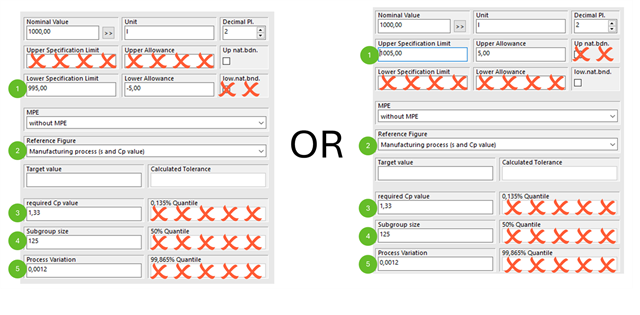

1. Reference-Figure: "Manufacturing process (s and Cp)"

In this case we assume normal distributed production process data and the user must provide in the "Master data" characteristics mask ...

- EITHER the upper limit OR the lower limit.

- The Reference figure "Manufacturing process (s and Cp value)".

- The minimum required capability index Cp of the manufacturing process.

- The total sample size of the data which has been used to calculate the standard deviation (our next field marked as '5').

- The calculated value of the standard deviation of the manufacturing process.

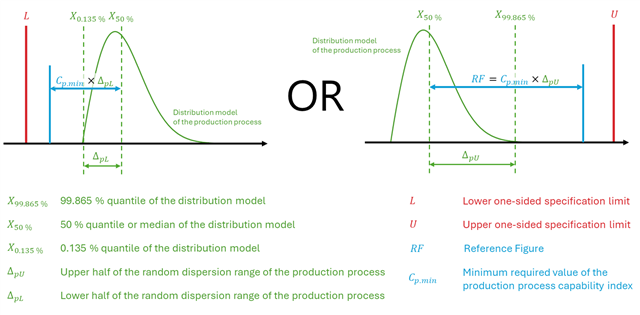

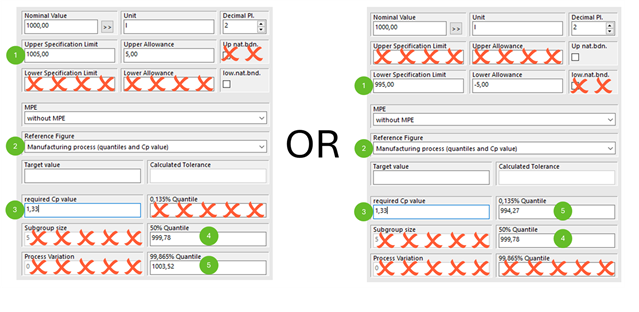

2. Reference Figure: "Manufacturing process (quantiles and Cp value)"

In this case we assume not normal distributed production data and the user must provide in the "Master data" characteristics mask ...

- EITHER the upper limit OR the lower limit.

- Reference Figure "Manufacturing process (quantiles and Cp value)".

- The minimum required capability index Cp of the manufacturing process.

- The 50 % Quanile of the distribution model which has been fitted to the manufacturing process data.

- If the upper limit is given, then provide only the 99.865 % quantile of the distribution model which has been fitted to the manufacturing process data.

If the lower limit is given, then provide only the 0.135 % quantile of the distribution model which has been fitted to the manufacturing process data.

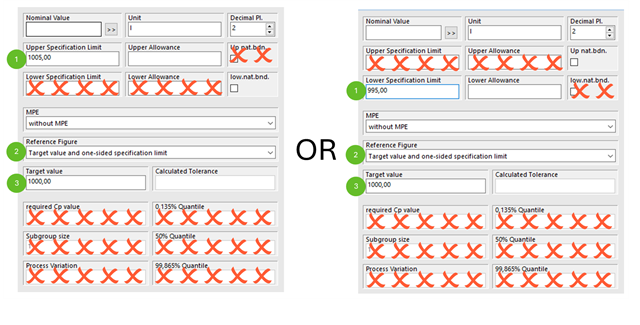

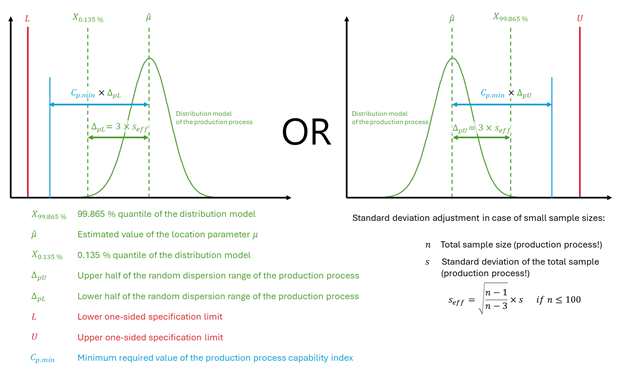

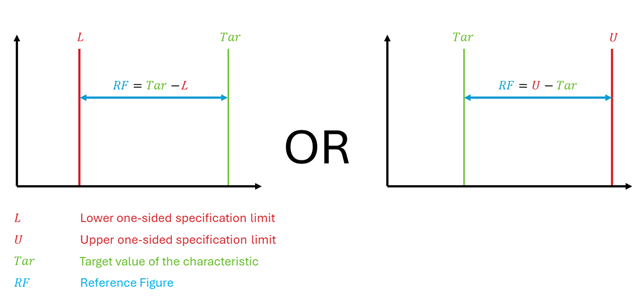

3. Reference Figure: "target value and one-sided specification limit"

In this case we assume arbitrarily distributed production data and the user must provide in the "Master data" characteristics mask ...

- EITHER the upper limit OR the lower limit.

- Reference Figure "Target value and one-sided specification limit".

- The target value of the characteristic.