There is no tolerance for one-sided specification limits. In this case, the VDA5 allows the tolerance to be replaced by a so-called reference figure RF. Two kinds of reference figures are available in our solara.MP software:

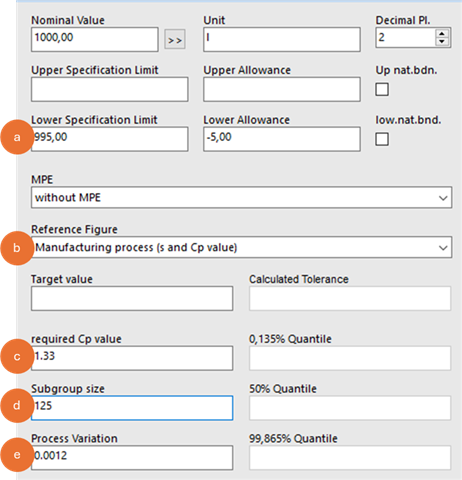

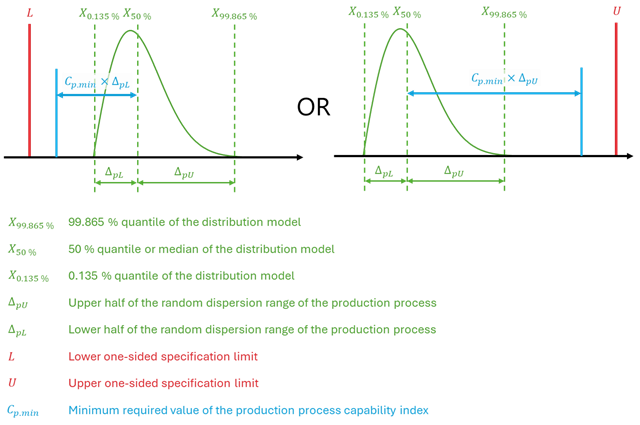

- Reference figure "Manufacturing process (s and Cp)"

In this case we assume normal distributed production process data and the user must provide in the "Master data" characteristics mask ...

- EITHER the upper limit OR the lower limit.

- The Reference Figure "Manufacturing process (s and Cp value)".

- The minimum required capability index Cp of the manufacturing process.

- The total sample size of the data which have been used to calculate the standard deviation (next field marked as 'e').

- The calculated value of the standard deviation of the manufacturing process.

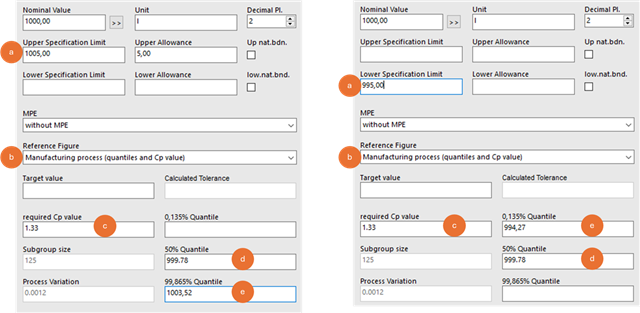

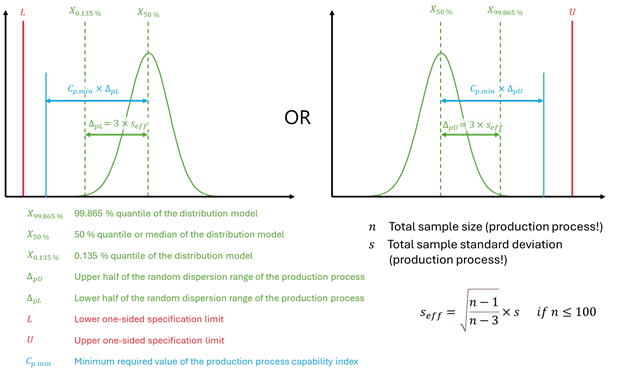

- Reference Figure "Manufacturing process (quantiles and Cp value)"

In this case we assume not normal distributed production data and the user must provide in the "Master data" characteristics mask ...

- EITHER the upper limit OR the lower limit.

- Reference Figure "Manufacturing process (quantiles and Cp value)".

- The minimum required capability index Cp of the manufactoring process.

- The 50 % Quanile of the distribution model which has been fitted to the manufacturing process data.

- If under (a) the upper limit has been used, the 99.865 % quantile of the distribution model which has been fitted to the manufacturing process data.

If under (a) the lower limit has been used, the 0.135 % quantile of the distribution model which has been fitted to the manufacturing process data.

Important: Do not fill in both, the 0.135 % quantile AND the 99.865 % quantile. Provide only the required quantile value!